What is Block Caving?

Block (gravity) caving is a bulk underground mining method, which allows large low-grade deposits to be mined underground. This method involves undermining the orebody to make it collapse under its own weight into a series of chambers from which the ore extracted. It is a useful technique to extend the life of large deposits previously mined by open pits, and it is a method increasingly proposed for new mines around the world. It was developed in the over a period of time (1917-1930) in the Globe-Miami Porphyry Copper district of Arizona as a response to the declining grade of the deposits.

Why use Block Caving?

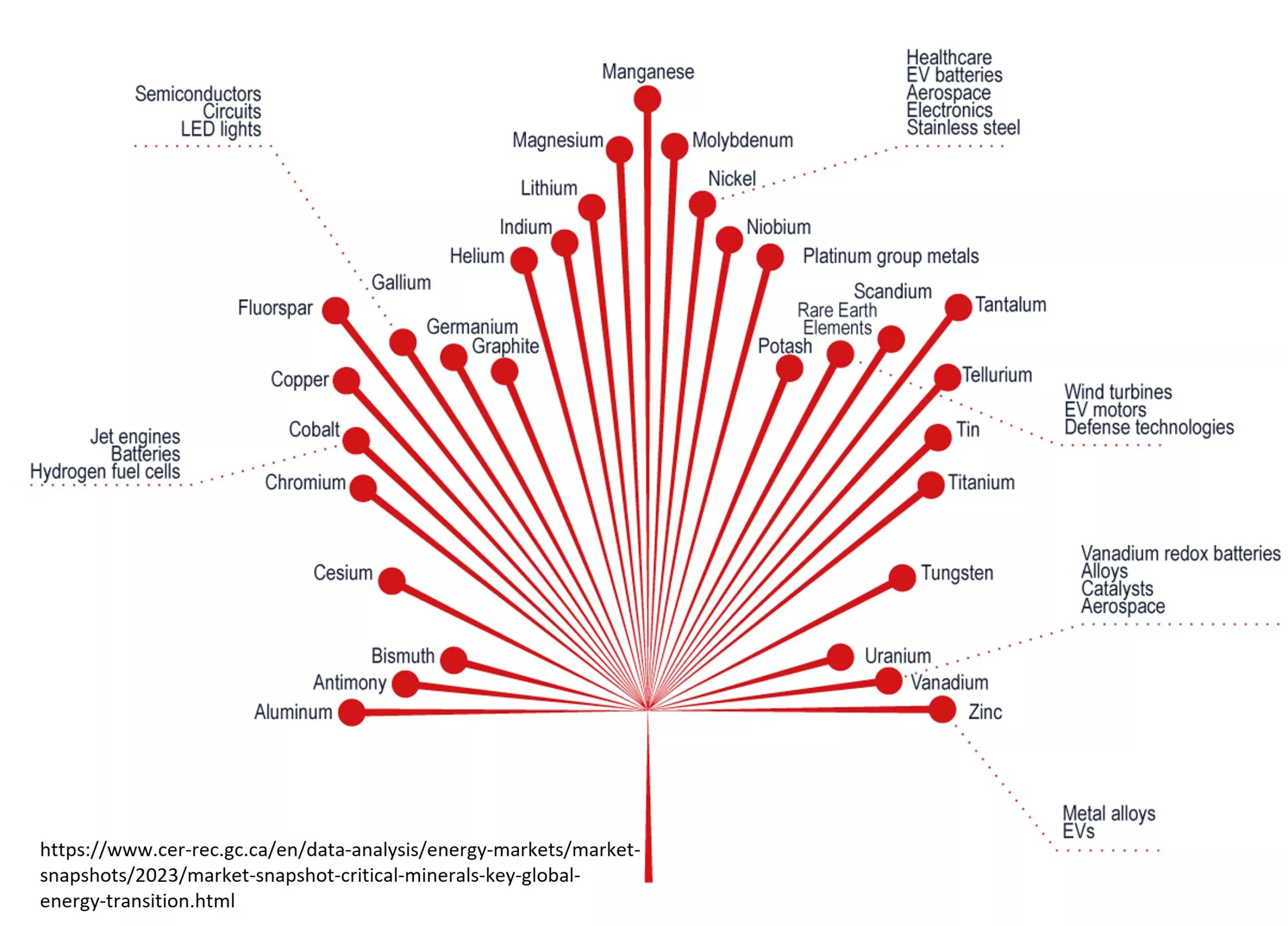

Most underground mining methods have prohibitively high operating costs, which only allow high grade deposits to be mined. Block caving has a high production rate, which means high capital costs at the start of the project but relatively low operating costs. If there is enough ore, initial capital will be recouped over the life of the deposit. This is why it is common at large copper porphyry deposits where other than open pitting, block caving is the most economical way to mine. El Teniente in Chile, Northparkes in Australia, Grasberg in Indonesia, and Resolution in Arizona are all examples of copper mines that use or plan to use block caving.

Despite widespread use in copper mines, block caving can be used in a variety of situations where low-grade, high-tonnage deposits cannot be efficiently accessed using open pit methods. Mining giant Rio Tinto is currently reviewing a possible investment in block caving at the Argyle Diamond Mine in Western Australia. High costs and low prices have hurt diamond miners in recent years and the company must decide is the substantial initial investment in a block cave will pay off.

How Does it Work?

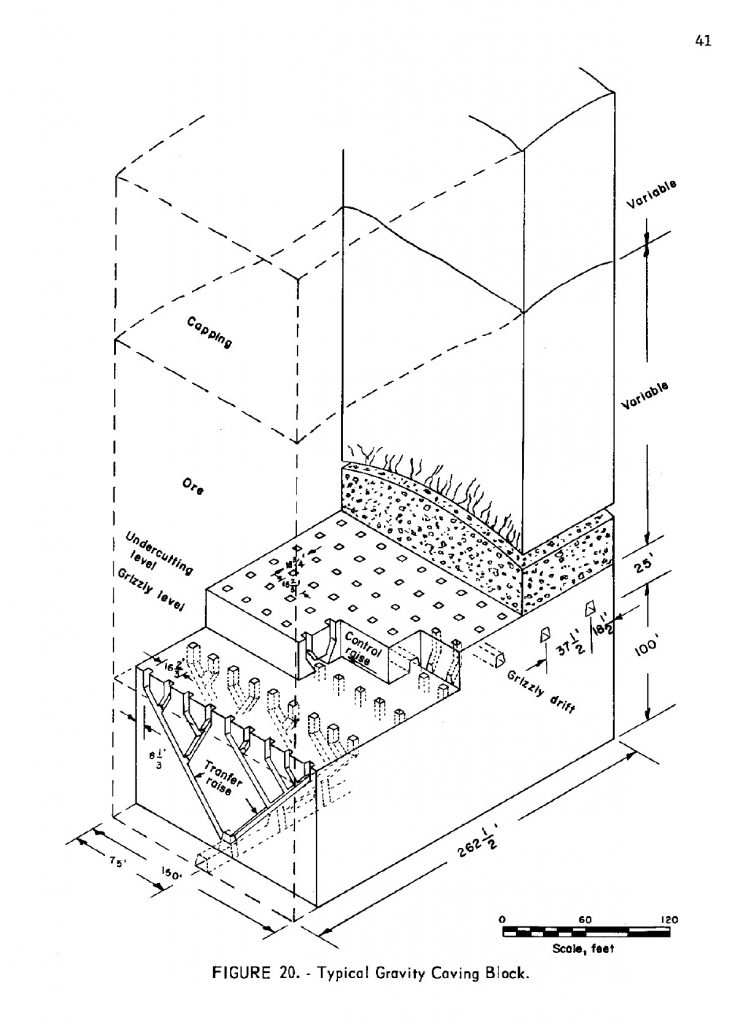

Block caving is achieved by undercutting the ore body and inducing gravity to drop the ore into collection points.

First, a “grizzly” level and haulage tunnel are put in below the undercut level. Then, a large “undercutting” or series of flat lying tunnels are driven into the orebody.

All three levels are connected by angled shafts to facilitate transfer of ore between them. Ore is then broken up so that it falls from the roof of the undercut level through the shafts to the grizzly level where it is collected and focused to the main haulage level. The undercutting is done in large square blocks to facilitate planning and control dilution of the ore.

In some mines, there are multiple block caving events, such as at the Ridgeway mine in Australia, when the initial block cave was depleted they went deep (1100 metres below surface) for their second block cave. In other cases such as Cadia, Palabora and Chuquicamata block caving was the solution to extending mine life when the open pit resources ran out. The Globe Miami mine is interesting case of reversal. It was a block-cave mine that was later turned into an open pit.

Potential Problems

Though a highly effective method of mining large low-grade deposits, there are some constraints. Implementing a successful block cave requires substantial planning, infrastructure and training – and ultimately a long lead time. With this long lead time comes greater political and economic risk as the social licence and the economic feasibility of the mine are contingent on world events which are outside of the company’s control. Related to this is the fact that once a block cave gets started it doesn’t stop. There is no “care and maintenance” comparable to other styles of mining. Finally, when block cave mining is up and running, there is noticeable ground subsidence in the immediate vicinity. Lastly, there is substantial risk of pit slope failure over block caving as shown by the pit wall landslides at Palabora, Bingham Canyon, Cadia and Chuquicamata.

Further Reading

- SME Mining Engineering Handbook (2011) Edited by Peter Darling Society for Mining, Metallurgy & Exploration Book

- Block-caving copper mining methods and costs at the Miami mine, Miami Copper Company, Gila County, Arizona (1965) Hardwick, W. R. U.S. Dept. of the Interior, Bureau of Mines PDF

- Empirical investigation and characterization of surface subsidence related

to block cave mining (2013) Woo et al. International Journal of

Rock Mechanics & Mining Sciences PDF - Open pit or block caving? A numerical ranking method for selection (2014) Rashidi-Nejad et al. The Southern African Institute of Mining and Metallurgy 2014 SOMP Annual Meeting PDF

- Local diamonds not cutting it (2017) Business News Western Australia Link

Subscribe for Email Updates