Introduction

The mining industry is undergoing a revolution. Due to increasing pressure from investors, regulators and communities the industry is rapidly evolving to higher levels of environmental, social and governance strategies (ESG) in a push to show that mining can be a clean and socially responsible industry. This is leading to significant leaps in innovation. In this vein, Gensource Potash Corp (TSX-V: GSP), has completely redesigned its potash mining operation from top to toe, achieving exciting improvements at every stage of the mining, processing and distribution chain. Their new technique for potash extraction: closed-loop selective solution mining has such a light environmental footprint that their Tugaske project in Saskatchewan did not require an Environmental Impact Assessment (EIA). This is no mean feat and exemplifies that mining companies are beginning to use ESG to maintain a social license to operate and take advantage of the booming market for sustainable development. Top ESG performing companies are more likely to deliver projects on time and exhibit 40% faster growth compared to the average. They are also viewed as less of an investment risk and are more resilient to fluctuations in market forces.

What is Potash and Why Do We Need It?

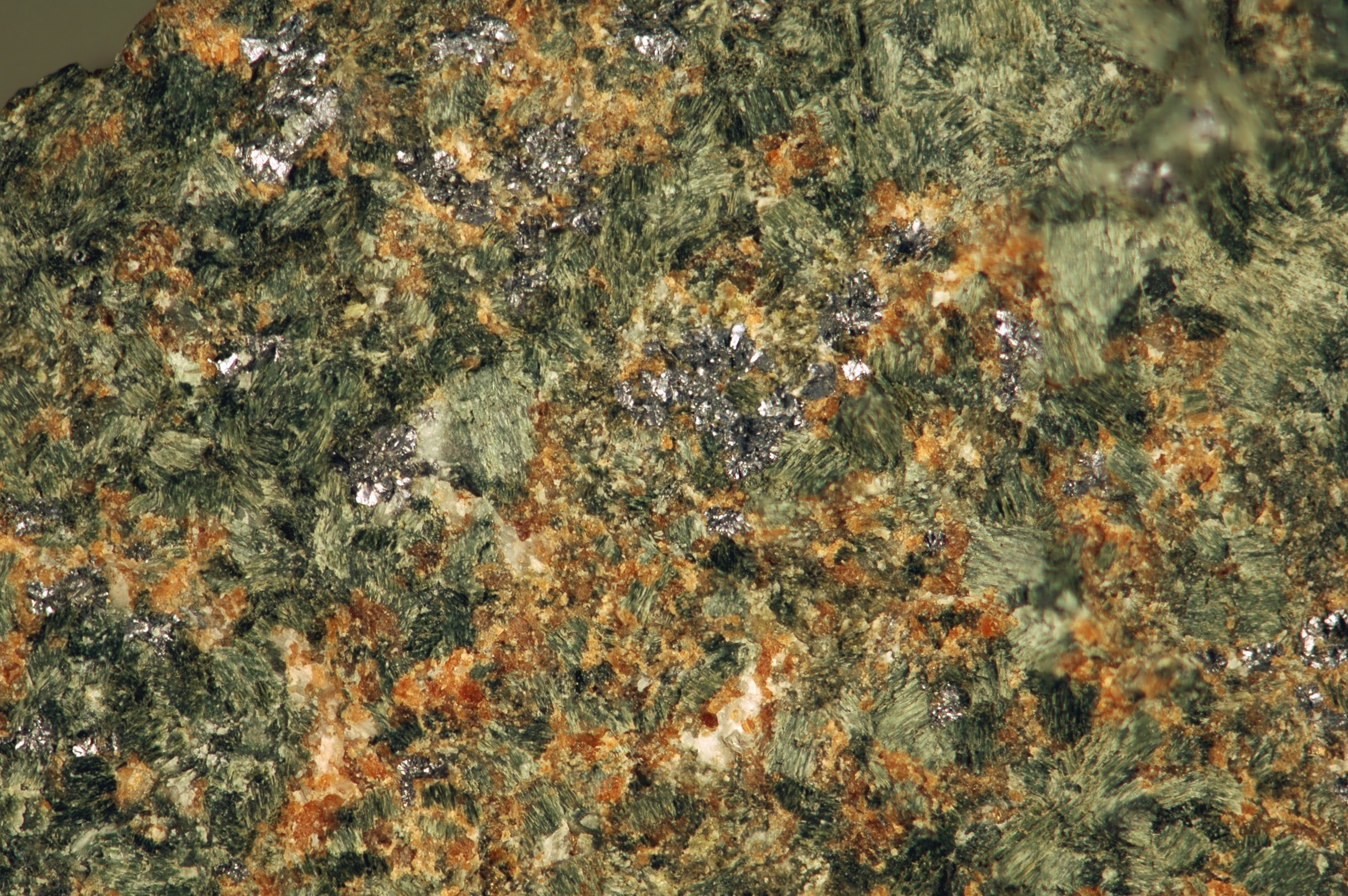

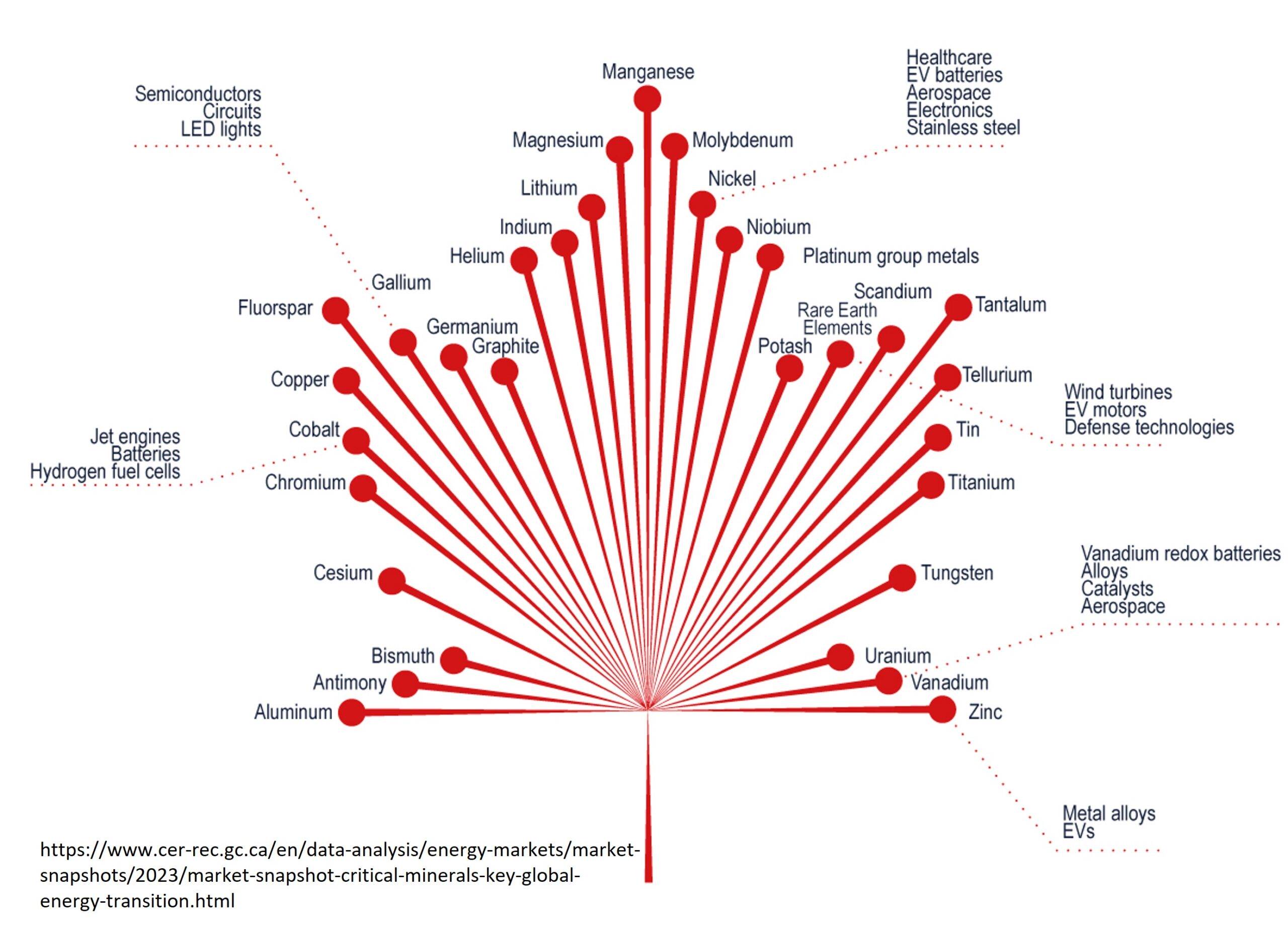

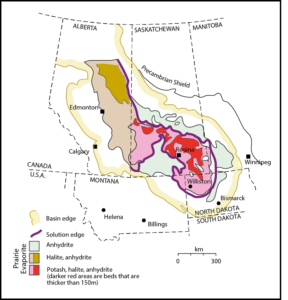

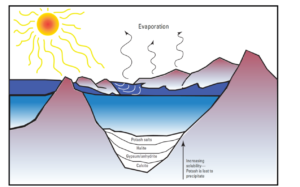

Potash is the common name for a range of potassium compounds and salts (K2CO3, KCl, K2SO4, KOH). Deposits are typically formed when seabeds or briny lagoons are exposed to high evaporation rates (Figure 1). Brine evaporation concentrates the salt in the water causing it to precipitate out of the solution, forming a salt with a pinky-orange hue (Figure 2).

The primary market for Potash is for fertilizer production. In the agricultural sector potassium is a necessary soil nutrient for growing produce. Plants use potassium to regulate water consumption, make strong stems and leaves, carry out photosynthesis, and to produce flowers and fruit.

With a projected global population of 10 billion by 2050, a steady supply of potash is needed to ensure larger, more nutritious crop yields and improved food security.

Potassium is also used for softening water and soap, and in drilling muds in the petroleum industry.

Environmental Issues with Potash Mining

Traditional potash extraction is carried out by either open cast drag-mining, or subsurface solution mining. Typically, solution mining requires large evaporation ponds at surface to concentrate the potash brought up from below so that it can be extracted. These ponds are often dyed a spectacular blue colour to enhance evaporation Figures 1 and 3).

Potash extraction via solution mining involves injecting a heated salt solution (NaCl – table salt) into the potash beds underground. Beneath the surface the sodium in the brine is exchanged for potassium as it interacts with the ore. The solution is then pumped back to surface ponds where it is evaporated forcing the potassium in the solution to precipitate out.

This type of extraction typically disturbs the environment in the following ways:

- Water use – The pumping of vast amounts of groundwater in the extraction process (~ 40 million litres per day) can lower the local water table. This can create resource competition with local communities and negatively impact local ecosystems.

- Decreased air quality – As with all mining projects, dust and greenhouse gas emissions associated with extraction, processing and transport are common.

- Fragmentation of local ecosystems – native grasslands and wetlands in particular, which are important natural assets providing seasonal drought and flood mitigation.

- Salination of local surface and groundwater – due to leakage of effluent and surface runoff from brine ponds and tailings storage facilities. This negatively impacts local aquatic communities and water quality.

- Ground subsidence – due to pumping of ground water for solution mining.

The new closed-loop selective solution mining method developed by Gensource Potash Corp effectively mitigates the environmental impacts listed above, which is why the Tugaske project does not require an EIA.

Gensource Mining Model and Extraction Method

Gensource operates out of the Canadian province of Saskatchewan, which hosts over a third of global potash reserves. A key innovation of Gensource’s potash initiative involves more smaller modular mines 1/10th of the size of typical potash projects (Figure 3).

Smaller mines have smaller, more localized footprints. Additionally, these modular mines will extract potash with 10 times the efficiency compared to their larger counterparts and operate for nearly twice as long (40 years). This will translate to greater job security for mineworkers. As such these mines are more likely to be accepted by communities. Further, the new closed-loop selective solution extraction method (Figure 4) removes the need for brine ponds and tailing storage facilities. This is achieved by:

- Recycling of solution brines – decreasing the amount of water used to extract ore by 75% using a closed loop circulation method.

- Using locally extracted natural gas for power, as opposed to coal.

- Removing the need for salt tailings or brine ponds – there is no possibility for contamination of local waters and there are no decommissioning risks.

Gensource Tugaske Mining Project

The Tugaske mining project is located in a rural village of the same name in Saskatchewan, Canada. It will host the first of Gensource’s modular closed-loop selective solution mines. The project will produce a minimum of 250,000 tons of potash per year. To achieve greater market stability, Gensource has incorporated vertical integration into its production plan. 100% of the potash produced will be sold to Helm Fertilizers Corp. If this model is successful, many more modular potash mines are expected to come online in the near future. The diminutive footprint of these modular mines coupled with the decreased number of procedures and investment required to get them to the production phase makes them low risk and highly scalable.

Deposit Overview

The deposit comprises high grade muriate of potash ore (KCl) located within the mid-Devonian (393.3 – 382.7 Ma) aged Prairie Evaporite Formation, which is the world’s largest potash reserve. The potash was deposited as the mineral sylvite (KCl) in discrete 30 m thick horizons within in a large, shallow marine embayment known as Elk Point Basin. The sylvite is intergrown with halite (NaCl). An extensive reef barrier known as the Presqui’ile Barrier block the Elk Point Basin from the open sea to the north. The combined effect of a low water supply with high evaporative rates resulted in the formation of brine lagoons and salt flats which precipitated potassium-, magnesium, sodium- and calcium-bearing salts (Figure 5).

The succession of salt composition in the strata is related to cyclic periods of sea level rise and fall in the basin. The sequence of precipitation of different salts depends on the relative differences in solubility between ions. Potassium is more soluble and will typically precipitate last in the sequence after halite, anhydrite and calcite (Figure 6).

Outlook

The market for potash demand has historically been stable and is projected to increase through 2022 and onwards. This is supported by a 20% growth in ore production from 2012 – 2016. Demand for all potash applications is projected to reach 45.6 million tons by 2021. In terms of ESG, the Gensource Tugaske project serves as a guiding light in an industry that is under pressure to raise its performance standards to meet the needs of a market increasingly geared towards sustainability.

Terminology

- Precipitate: When a salt is crystallised from a solution

- Muriate of potash: Salt composed of potassium and chloride

- Environment, social and governance: three core components used to determine the social impact and sustainability of a business enterprise

List of Companies Mentioned

- Gensource Potash Corp. (TSX-V: GSP) (website)

Further Reading and Sources

- The Gensource Tugaske Project (website)

- Gorostiza S, Sauri D (2019) Naturalizing pollution: a critical social science view on the link between potash mining and salinization in the Llobregat river basin, northeast Spain. Philosohical Transactions of The Royal Society B – Bological Sciences 374:8. (academic article)

- International Fertilizer Industry Association, United Nations Environment Programme (2001) Environmental aspects of phosphate and potash mining (UNEP/IFA) (pdf)

- Ober J A (2018) Mineral commodity summaries 2018. US Geological Survey, Reston, Virginia (article)

- Yager D B (2016) Potash – A vital agricultural nutrient sourced from geologic deposits. US Geological Survey, US Geological Survey, Reston, Virginia (article)

- Devonian potash in the Western Canada sedimentary basin. In: Saltwork Consultants. (website)

Subscribe for Email Updates