Introduction

EDITORS NOTE: Following our recent article on anorthosites, a reader asked us about an industrial minerals project in Greenland involving anorthosites. With Greenland being in the news lately (but apparently not for sale), we thought it might be a good time to take a look. In 2025, Greenland has once again become a hot topic so we’ve updated this article to reflect the current state of this project. This is also good time to mention that we happily take article requests and we love to write about projects that involve interesting geology or exploration stories.

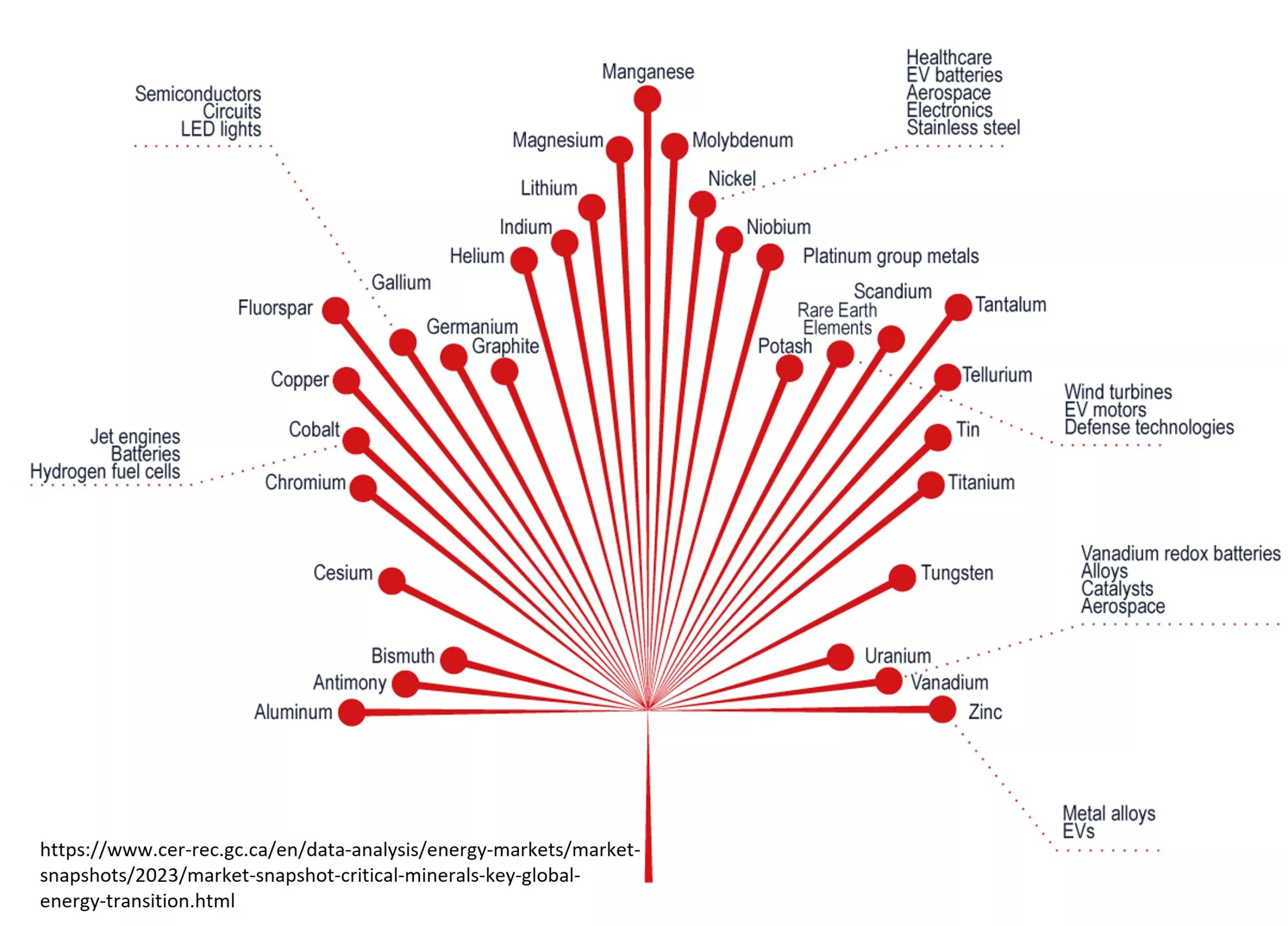

While traditional mining projects usually involve exploration for in-demand commodities, we occasionally run across projects that work backwards: They find unique mineral deposits and try to create a demand. Typically these involve non-metallic mineral deposits since metallic deposits have a more easily measurable value. We’ve seen this before with companies attempting to build business cases for hydrothermal graphite deposits, high purity dolomite as a magnesium source, silica sand as a source of fracking material, and a wide variety of gemstones. In this case, Hudson Resources (TSXV: “HUD”) [As of 2024 Hudson is now Anortech CVE:ANOR] has staked a large calcium-rich anorthosite occurrence in Greenland and built a business case for it’s potential as a source of industrial raw materials with applications in the fiberglass, alumina, filler, paint and cement markets. The company completed mine construction in 2019 and in 2022 rebranded the operating entity of the White Mountain Anorthosite mine to Lumina Sustainable Minerals. Lumina expects an output of 200,000 tonnes of anorthosite in 2025.

Geology, exploration and products

Generally, anorthosite occurrences in Greenland are structurally deformed and heavily metamorphosed which complicates revealing their genetic relationships. White Mountain with 1300 m height, the Greenlandic name is ‘Qaqortorsuaq’ (i.e. the big white), was observed in 1946 during fieldwork carried out by the Geological Survey of Greenland on the west coast of Greenland. The anorthosite occurs as a scull-cap on the mountain north of the borderland between the two pre-Cambrian complexes, the late 1.9 Ga old Nagssugtoqidian orogen, and the early Kangamiut complex.

The Qaqortorsuaq anorthosite occurrence was calculated to be 3 to 4 cubic km in size with 27 Mt of indicated and 32 Mt of inferred resources. According to their most recent NI 43-101 Preliminary Economic Assessment (2015) these resource calculations are based primarily on surface sampling and trenching, with only about 10 drill holes recorded. This level of data collection is typical of a very early stage exploration project and doesn’t give a lot of hard data, but it’s not surprising given that the primary goal of the company was not to define the resource, but to prove the marketability of that resource. Somehow they managed to open a mine on that data.

What’s so special about the Qaqortorsuaq anorthosites?

Anorthosites are composed of 90 to 100% of calcium-rich plagioclase feldspar. It forms a mineral series with a range of compositions from sodium-rich albite (NaAlSi3O8) to calcium-rich anorthite (CaAl2Si2O8). The content of Al increases with the content of Ca (often expressed as the An% index) in the plagioclase and in the rock as a whole. There is also direct correlation between the ease of plagioclase solubility in acid and An% content: higher Ca content increases Al content and leads to higher mineral solubility. Greenland’s anorthosites contain SiO2 – 50%, Al2O3 – 31%, CaO – 15%, Na2O – 2.2%, Fe2O3 – 1% with An% between 60 and 90%. The high solubility of these anorthosites means that the constituent elements can be extracted more easily and without significant waste or environmental concern. That last point is a good part of how this mine was permitted so quickly. For Hudson, the main advantage of their project is that the rock is the product. Unlike metal mines that must process tonnes of rock to get a few grams of metals, these anorthosites are basically crushed and shipped out. The operation itself is not much more complicated that an aggregate quarry and there is no industrial waste since processing is done by the end customers. Aside from the minimal local impact there’s an even bigger environmental story here as many of their proposed end uses offer offer significant waste and emission reduction alternative to traditional products:

Anorthosite in the production of fiberglass

Kaolin, a clay rock consisting of kaolinite (Al2(Si2O5)(OH)4), is typically used in manufacture of paper, plastics and fiberglass. The first step of the manufacturing process for fiberglass includes melting the silica sand, limestone (a sedimentary rock consisting of calcium carbonate, CaCO3), kaolin and other minerals until liquid forms. The anorthosites are a potential replacement for kaolin with a reduced melt time (by 33%), lower heavy metal content, lighter stronger fibers, less waste and reduced NOx, SOx and CO2 emissions. Hudson reportedly cut a 10 year deal with Owens Corning to purchase a “significant” portion of their anorthosite production for fiberglass production.

Anorthosite as an alternative specialty aluminum source.

Buaxite is the world’s largest source of aluminum by a large margin, but processing Bauxite into alumina (aluminum oxide Al2O3) generates a large amount of waste material and CO2. Refining the bauxite using the Bayer Process generates 1 to 2 tonnes of red mud tailings per 1 tonne of alumina during the digestion with sodium hydroxide (NaOH) to receive alumina. On the other hand, test work undertaken by SGS Canada Inc.’s Lakefield has confirmed 270 kg of alumina recovery per 1000 kg of anorthosite by hydrochloric (HCl) leaching. This process also produces usable industrial by-products like amorphous silica and calcium silicate.

Anorthosite as a source of white cement

Hudson has proposed that their anorthosites can be used to produce a CO2 free, heat-resistant, acid-resistant and high-durable white cement with numerous potential applications. The latter product is supposed to replace Ordinary Portland Cement (OPC), which releases nearly 0.9 tonnes of CO2 for each tonne of cement produced.

Conclusion and Discussion

When your deposit is sitting on a treeless landscape on the top of a small mountain, the lack of an extensive drill program can be perhaps be forgiven. Hopefully the company has a reasonably good idea of the An% of unexposed anorthosites in the larger resource. Besides, this project seems to be more of a story about good marketing than about good geology. The properties of high An% anorthosites have been known and mined for decades in Norway, but their use has been primarily restricted to road aggregate and as an additive to white concrete. Other uses have been tested but not implemented on a large scale. Credit goes to Hudson’s team for making the case and making the sale to at least one big client. There’s no doubt that part of that success is due to environmental message that they’ve crafted. Ten years ago a low carbon industrial option might not get much attention, but the time is right for low emission processes. It didn’t hurt that the project had a relatively small barrier to entry compared to other mining operations with simple processing and operations.

Time will tell whether this project will translate into a return for investors, but at least this junior can put “built a mine” on it’s resume.

Further Reading

- Anortech [In 2024 Hudson rebranded to Anortech] (Company Website)

- Lumina Sustainable Minerals (Company Website)

- Norwegian anorthosites and their industrial uses, with emphasis on the massifs of the Inner Sogn-Voss area in western Norway (PDF)

- A report/summary of knowledge about Norwegian anorthosite prospecting – in relation to Greenland anorthosites (PDF)

Subscribe for Email Updates