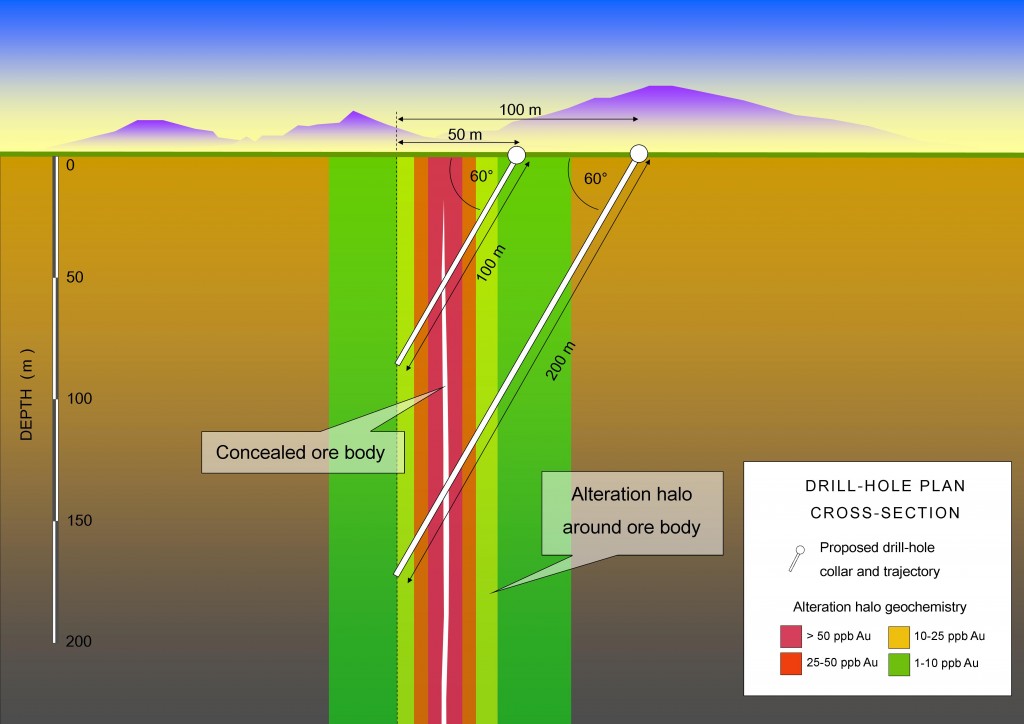

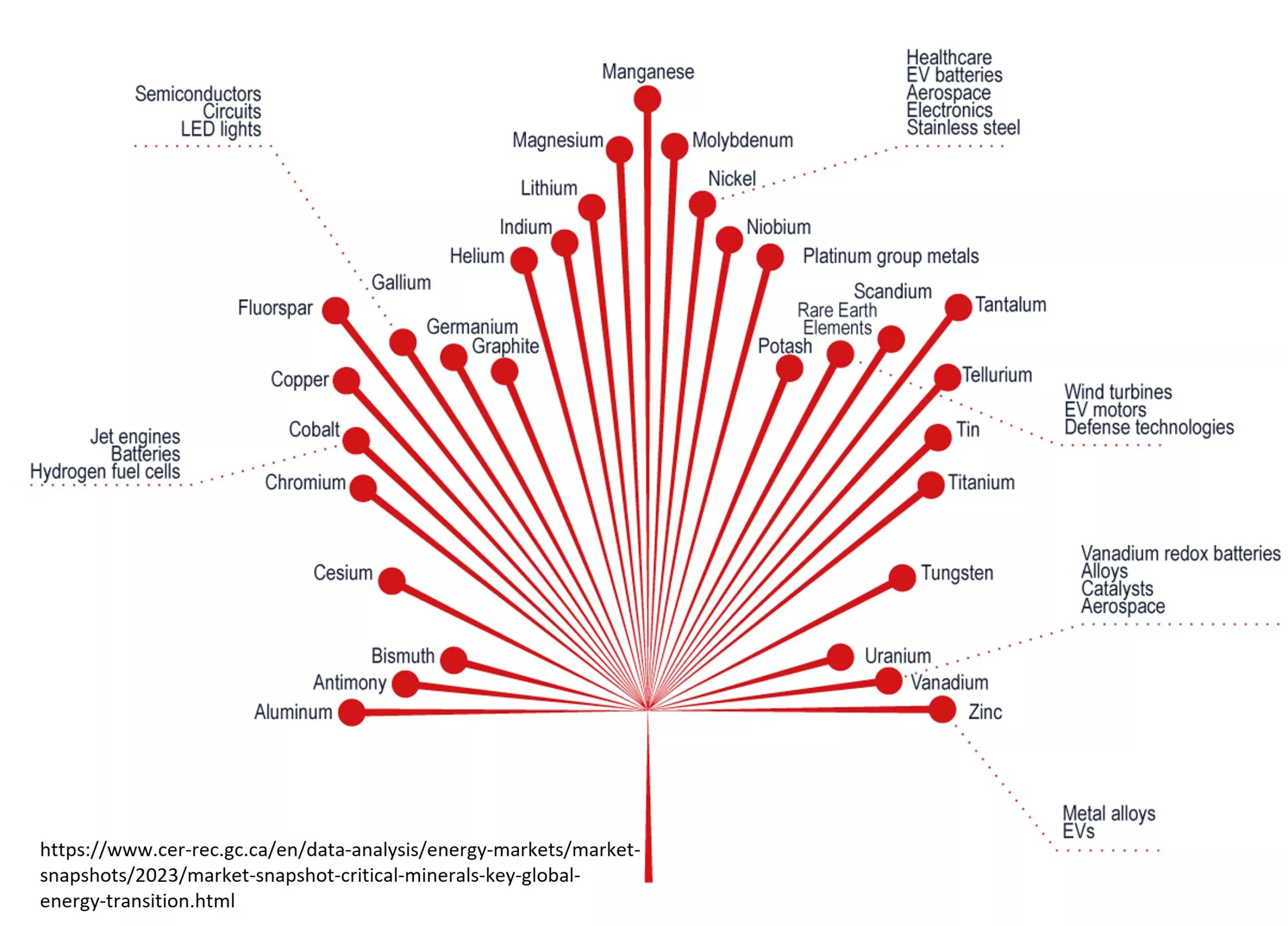

The phrase “exploration geology” calls to mind a lonely geologist and a drill rig in the middle of a windswept, rocky expanse miles away from civilization. While that is the case in some instances, exploration geology activities are not restricted only to pre-production mine sites. Rather, drilling is a crucial part of the mine production process. Mines that have been active and producing for years still have exploration drilling programs.

Drilling programs are essential, due to the constraints of our current methods of discovering what is beneath the earth’s surface. Seismic studies, magnetometry, and geological modelling all have their limitations, and the best way of determining what is under all of that soil and vegetation is still to actually take a look. This is especially important for underground mines, as the safety and integrity of the underground environment depends on knowing exactly where faults and other weaknesses in the surrounding (or country) rock are.

Logging Drill Chips in Queensland

While supervising drilling activities at a large underground metallurgical coal mine in rural Queensland, Australia, I was performing routine sampling of rock chips produced by my drill rig and drill crew. Our target depth was roughly 250 meters, and we expected to encounter two well-known coal seams and a few minor ones. The coal measures in this part of the Bowen Basin have been extensively mapped, and are well understood. This part of the drilling program was supposed to be simple. We were on a section of the mining lease that would soon be part of the larger underground mine. In fact, we were less than a kilometer away from the advancing longwall, which is the part of the mine that is being actively worked. On this particular day we were drilling for coal quality, which means that I was simply supposed to confirm the data in our computer models about the depth and quality of the coal seams. The major faults in the area had been identified, and the senior mine management team was confident in the data we had collected to that point.

As our drill depth closed in on 200 meters the offsiders, or driller’s assistants, set down basket after basket of rock chips in neat rows on the ground for me to examine, describe, and record. With one basket load per meter of drilling, we had been keeping a good pace through the morning.

I was logging about ten meters behind the drill crew when one of the offsiders approached me with news that the drill was failing to produce any chips. I told him to let the driller know to keep going, and stopped logging to watch. Basket after basket was empty, so I marked the ground where each meter of chips should have been with pink spray paint. With that placeholder, I would not forget and log incorrectly. After eight meters of no returns, the drill finally produced chips. The offsider set down a meager pile, and I hurried over to take a look.

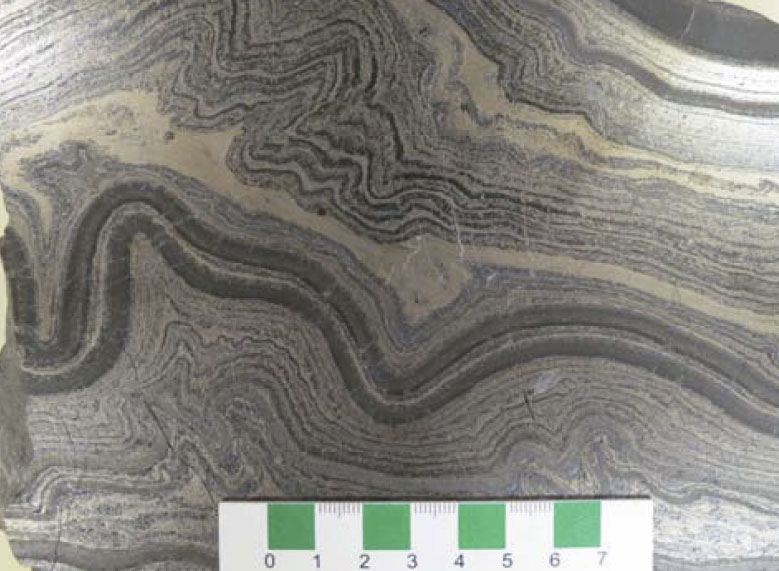

I was incredulous as I scooped up a loose pile of smooth, rounded rocks ranging from blueberry to cherry size. The sample contained many different types of rocks, including good-sized pieces of what looked to be pure quartz. Some schists were also present, and I was surprised at this since nothing similar to these metamorphic rocks was represented anywhere else on the mining lease. I set my handful of rocks back on the pile and waited. A few moments later, the offsider was back with another set of chips. Again, the sample was a collection of well-rounded rocks of various sizes from small to large pebbles.

There was no matrix connecting any of these rocks. When you hand a geologist a sample like this, it is a safe bet that you will be told that they are from a river. Poor sorting of rocks means that they have multiple sources, and the high degree of rounding means that they have travelled a great distance and had their sharp edges eroded away.

The next load of chips was the same, but the one after that was simple sandstone again. Prior to the section of no returns followed by what I was now calling the fluvial (river) section, we had drilled through sandstone and siltstone partings consistently for at least 30 meters. In the Bowen Basin, sandstone and siltstone are often found between coal seams. River deposits, however, are not.

I stopped the drill crew after another few meters of simple sandstone chips and called the senior mine geologist. I explained the situation, and it’s fair to say he was skeptical. No one working on this lease had ever found evidence of an underground river. The senior mine geologist came out to inspect the chips firsthand and brought along printouts of the 3D model of that part of the mining lease. We studied the model but found nothing; no indication of an underground river.

Still, the physical evidence does not lie, and we were in an area of known heavy faulting. We now had evidence that an underground river exists in the middle of this heavily studied major mining operation. The longwall excavation was postponed until additional geotechnical studies could be carried out. This is just one example of how geologists are frequently reminded that there is always more to know about the environments in which we mine.

Subscribe for Email Updates