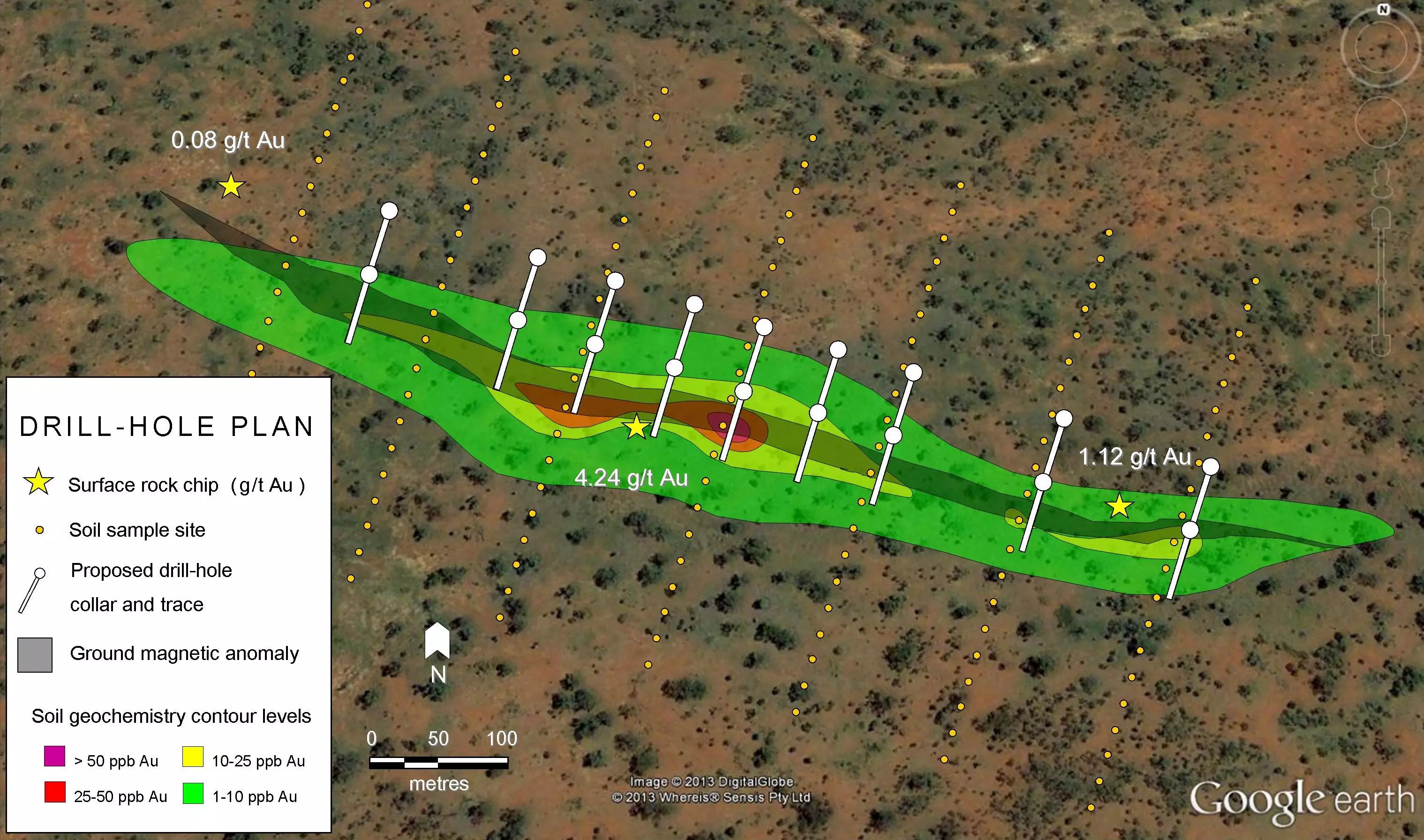

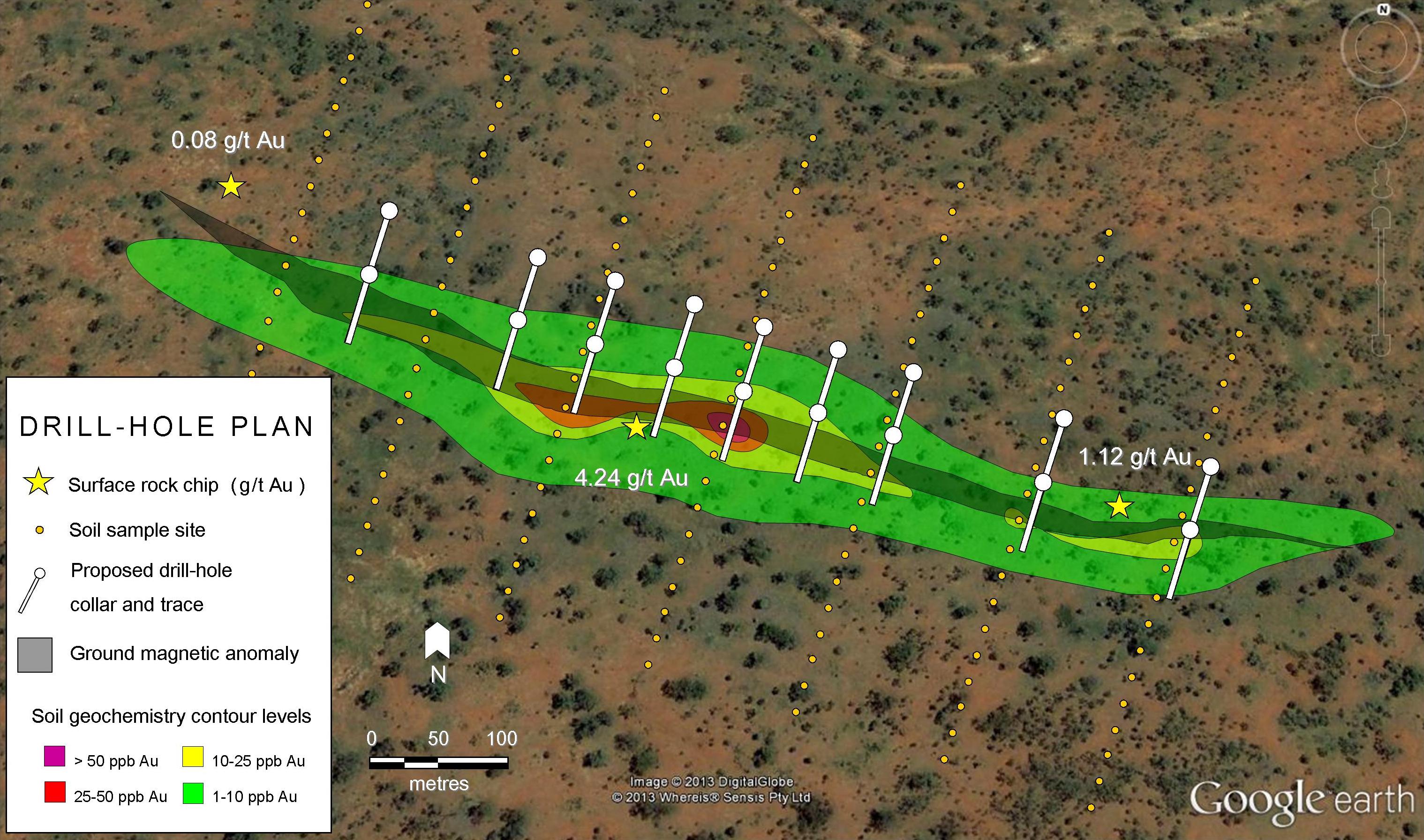

A successful soil sampling programme will result in a map of geochemical anomalies. The next step in exploration is for the geologist to design a drilling programme.

The exploration geologist uses several lines of evidence, both geophysical and geochemical, when developing a drilling proposal.

Rationale

The purpose of drilling is to confirm if anomalies in data are real and provide further evidence of a concealed ore deposit. Anomalies can be geochemical and/or geophysical. Anomalies are often ranked according to their strategic and geological rating. Those ranked highest are normally drilled first.

A geochemical anomaly is an unusually high level for a particular element. To be anomalous the concentration of the element needs to be at least a magnitude or higher than the element’s background level. When the anomaly involves several sample points and has a consistent geometric shape, it’s more likely to exist, and a greater confidence is placed on the existence of mineralisation.

Geophysical anomalies are unusually high or low points in the data which define a region of peculiarity. Geophysical techniques are indirect methods of mineral exploration. A mineral deposit may affect a certain geophysical parameter, which results in an anomaly. Not every geophysical anomaly indicates an ore body so geophysics is usually used together with geochemistry, not as a stand-alone technique.

The exploration geologist uses several lines of evidence, both geophysical and geochemical, when developing a drilling proposal. The proposal needs to have robust evidence, preferably from several different sources, before seeking a budget from directors and shareholders.

Designing A Drill Programme

The design of a drilling programme depends on whether it is designed to discover a new deposit or for delineating an existing resource.

Resource definition requires drilling at close spacing to provide a high level of certainty and confidence in the results. If an ore deposit is variable in grade then a large number of drill-holes will be required to define the resource. For deposits with a consistent grade, much less drilling is needed. Gold deposits are usually variable in grade over short distances, so a large number of drill-holes are needed to define this type of resource. Resource geologists and modellers “cut” the data to remove the highest gold values. This provides a closer approximation of the total resource and its average grade.

Planning A Drilling Programme

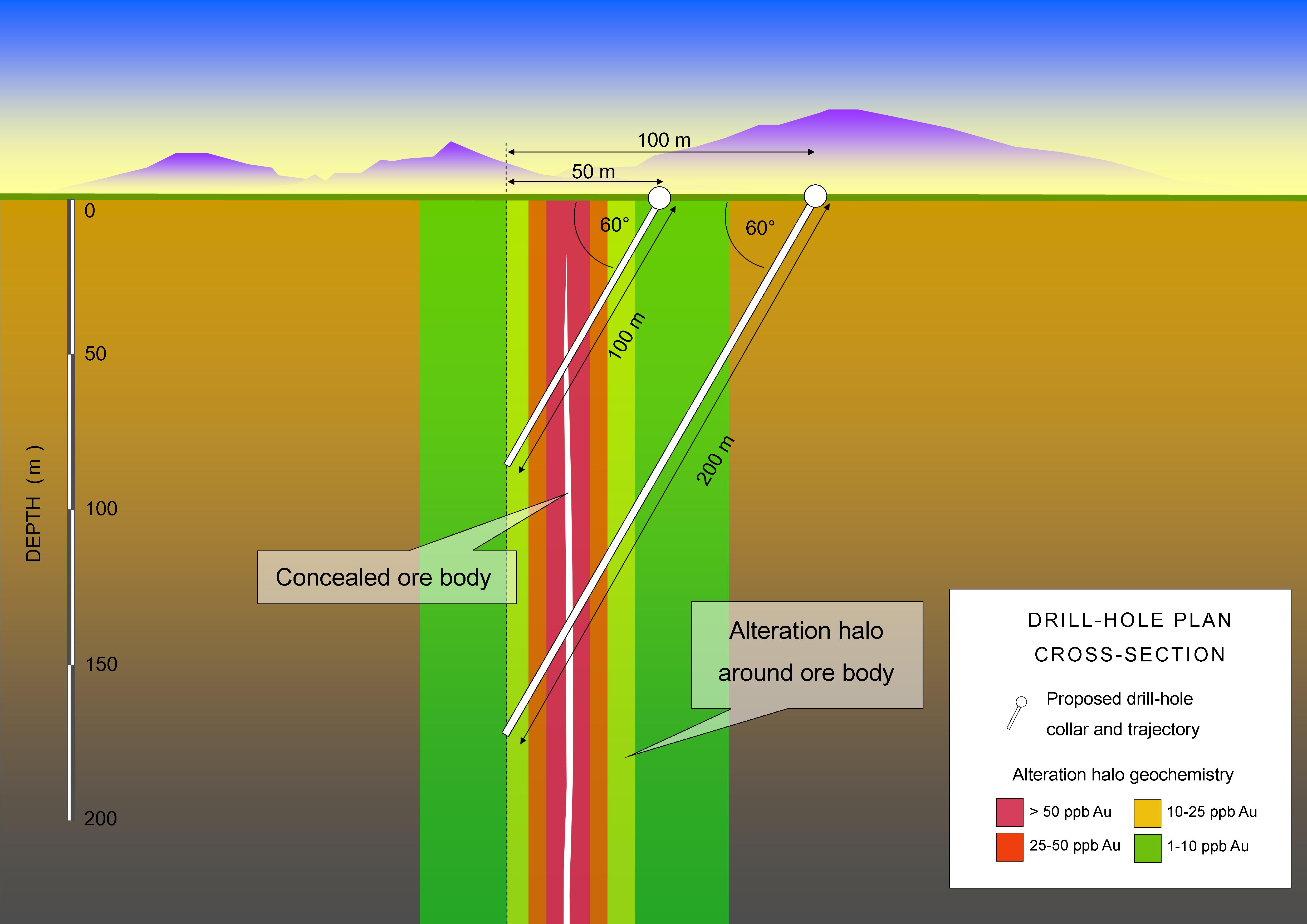

In the example shown in the image below a number of angled holes at 60° are designed to intersect at depth with the mineralisation that is causing the surface geochemical anomaly. The mineralisation is assumed to plunge almost vertically due to a known steeply dipping rock structure in the area. Hydrothermal alteration along this structure has resulted in a strong magnetic low, which is coincident with the soil geochemical anomaly.

Dispersion of elements from the ore body into the neighbouring country rock has resulted in the formation of an alteration halo. Dispersion of elements at the surface has also occurred causing a soil geochemical anomaly. The coincident geochemical and geophysical anomalies provide very good evidence for the drilling proposal.

Scattered highly mineralised rock chips found at the surface in the area indicate the potential underground ore grades. The spacing between drill-holes is designed to maximise the chance of intersecting the ore body while also gaining some understanding of its extent along the line of strike.

Drilling Methods

There are various drilling methods used in exploration. Cost is often the biggest decider of what technique is chosen.

Diamond Drilling

The best sample achievable through drilling is the diamond drilling method which produces core. A great deal of geological, mineralogical and structural information can be obtained from diamond drill core. Cross-contamination from one adjacent interval to the next is virtually absent. Diamond drilling is used for deep holes of approximately 300m or deeper. Diamond drilling is also the most expensive and slowest form of drilling.

Reverse Circulation

Reverse circulation or RC for short, is the most commonly used drilling method in the minerals exploration industry, mainly because it is cost effective and fast. A drawback to RC drilling is that less information can be obtained when using this method. This is because the samples produced consist of a mixture of small rock chips over each metre interval, so structural information is lost. Some contamination between adjacent intervals can occur and this should be kept in mind when interpreting the results. RC is useful for drilling holes to a depth of 300m. With the addition of extra high powered compressors and boosters, depths up to 500m are possible.

Percussion Rotary Air-Blast

Percussion rotary air blast or RAB is one of the cheapest forms of drilling. It is also the fastest. It is a very good technique for quickly drilling a large number of shallow (0-30m) holes across a deposit. Unfortunately, the technique produces samples of fine dust and chips that are often cross contaminated with material from other intervals. Drilling has to stop when groundwater is encountered as the hole quickly becomes clogged with mud.

Surveying A Drill Hole

The deeper the drilling the greater is the need for down-hole surveys. These are important drill holes can be very off course. A survey will confirm the actual angle and direction of the holes at a specific depth. Typically, surveys are conducted every 30 metres. However, sometimes there is a need to obtain surveys every 15 metres, especially when the hole is being deliberately redirected using navigational drilling techniques. When the surveys are plotted using 3D-modelling software the trajectory of the drill-hole relative to the target is revealed. Monitoring of the orientation of the hole during drilling allows the driller to make minor adjustments which can result in some degree of control over the drilling direction.