Aluminium (or aluminum) is the thirteenth element on the periodic table. It has the symbol Al, which is an abbreviation of the Latin word alumen.

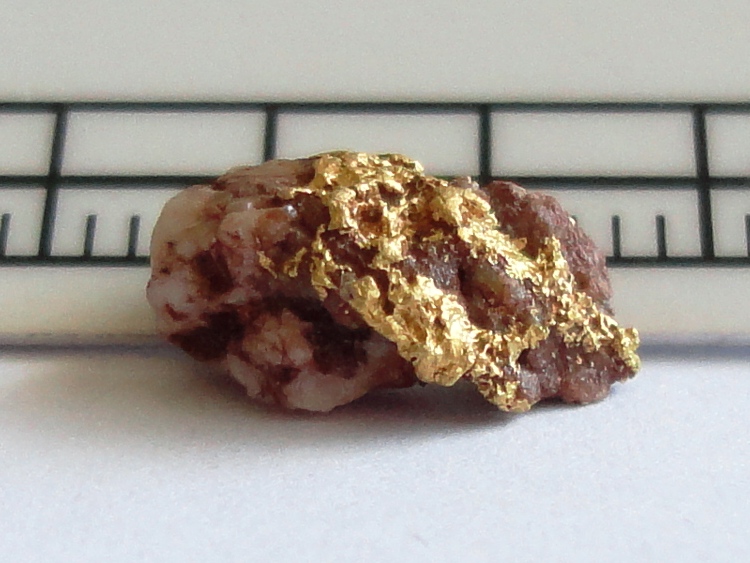

Aluminium is a silvery white, soft and ductile metal (Figure 1). It is highly reactive and has a low density of only 2.7 times greater than that of water. The metal has a relatively high thermal and electrical conductivity. It doesn’t corrode easily, due to the oxide of aluminium which forms immediately on freshly exposed surfaces and protects the metal from further oxidation.

Aluminium Extraction

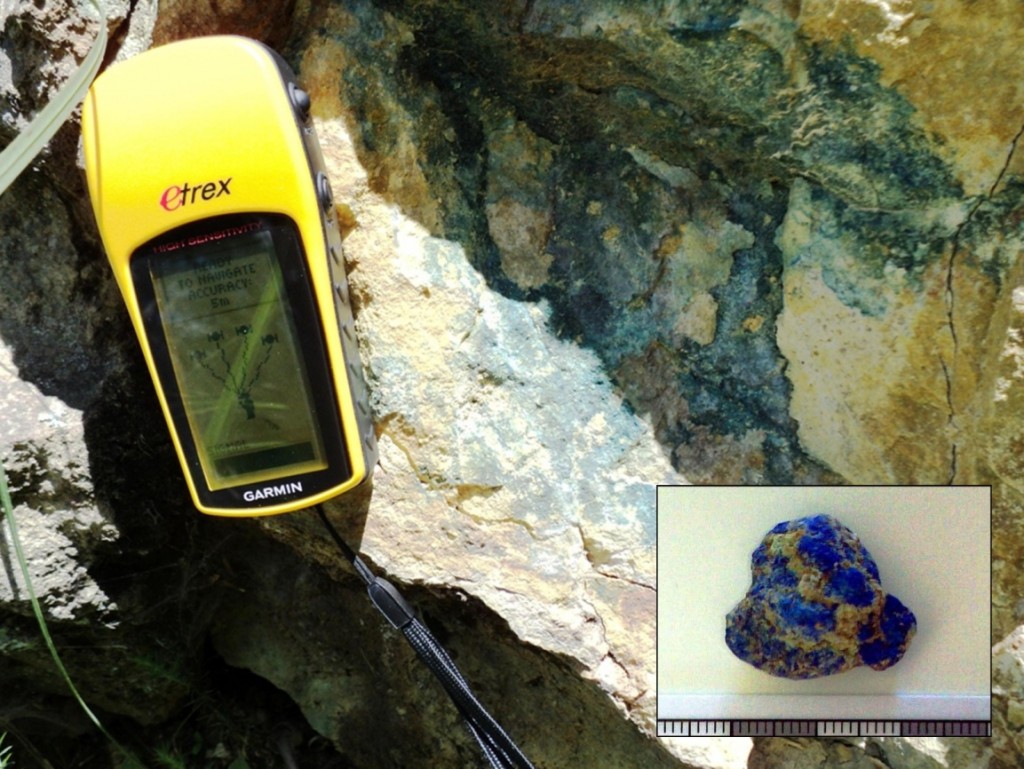

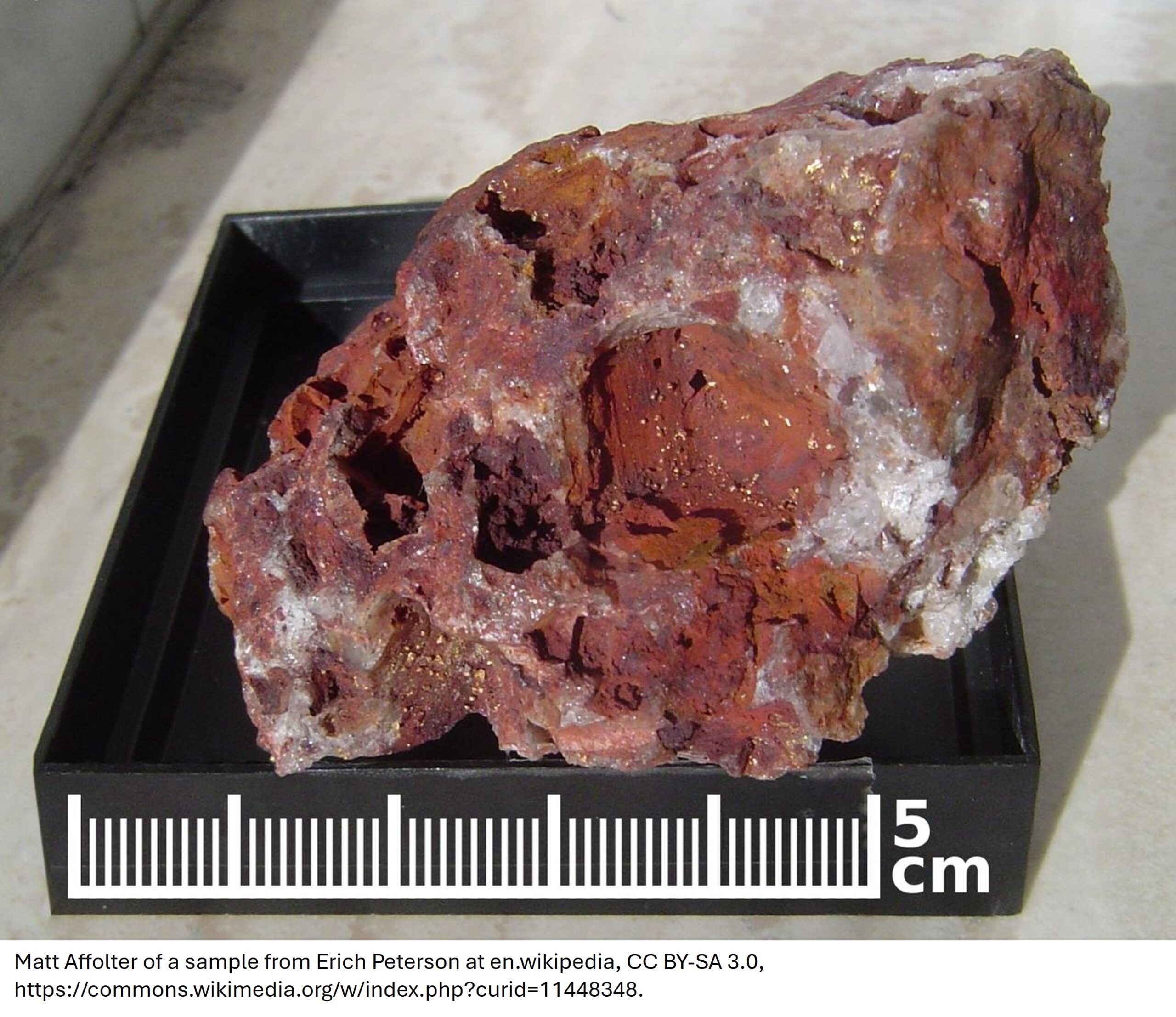

Aluminium is the most abundant metal in the Earth’s crust. In igneous rocks, it combines with oxygen and silicon to make up the common minerals called feldspars. When feldspars are weathered; sodium, calcium and potassium are removed leaving behind layers of aluminium-rich clays. Intense lateritic weathering results in the removal of silica as well, resulting in the residual accumulation of aluminium in the form of bauxite. The main bauxite mineral is called gibbsite, an aluminium hydroxide. Aluminium is extracted from bauxite rather from than clays and feldspars as processing required for the extraction is much easier.

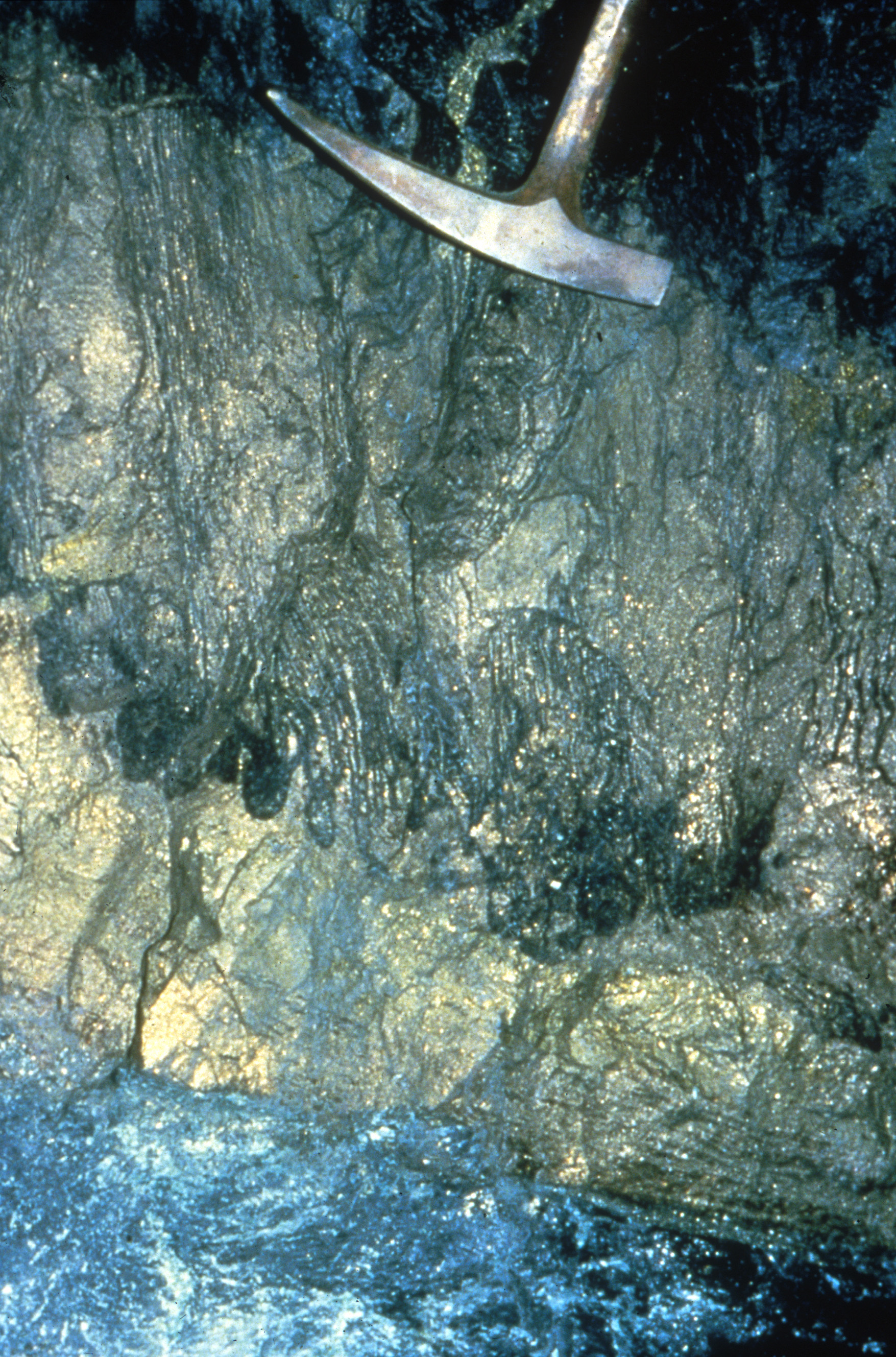

Native metallic aluminium is extremely rare in nature. It is only found in unusual and extremely oxygen-poor environments.

The rarity of the metal, meant that during much of the 19th century, aluminium was considered a precious metal, and was sometimes more expensive than gold..

It wasn’t until the 1880’s that a cost effective method of extracting aluminium from bauxite was discovered. The first stage of the extraction process is called the Bayer Process where bauxite is dissolved in a hot pressurised caustic soda solution, at around 200°C. Pure aluminium hydroxide is deposited from the solution as it cools. Aluminium oxide is then created by drying the aluminium hydroxide at a very high temperature, above 1000°C. The last stage of the process involves mixing aluminium oxide with molten cryolite.. The cryolite acts as a flux, reducing the temperature at which the aluminium oxide melts. Passing a current between electrodes results in the deposition of molten metallic aluminium around the cathode or negative electrode; a process called electrolysis.

What are its uses?

Aluminium is a good thermal and electrical conductor; just over half that of copper’s, which is one of the best conductors of heat and electricity. However, it is much lighter in weight than copper. Aluminium’s high conductivity to weight ratio is the reason it’s used for high-tension power lines. Unfortunately, it can no longer be used in home wiring as it was found to be the cause of many electrical fires.

The metal’s high reflectivity makes it an ideal choice for coating surfaces to make them reflective. For example, reflecting telescopes have an extremely thin coat of aluminium applied to the front surface of mirrors. Unlike silver which was traditionally used, aluminium does not tarnish.

The high resistance to corrosion and high reflectivity makes aluminium also excellent in reflective and “metallic” paints where it is added to a base as very fine particles.

The oxide layer on the surface of aluminium can be thickened by a process known as anodising. This increases the metal’s corrosion resistance and makes the aluminium harder wearing. The oxide layer that is produced by anodising can be dyed to create a multitude of hard wearing colours.

Aluminium oxide is used as an abrasive. It can be made commercially by heating bauxite above 450°C, in a process called calcination. Corundum which is a naturally occurring oxide of aluminium is one of the hardest minerals known, having a hardness of just slightly less than that of diamond. Varieties of corundum include the gemstones sapphire and ruby. A small amount of chromium in ruby causes the red colour, while small amounts of iron and titanium causes the blue in sapphire.

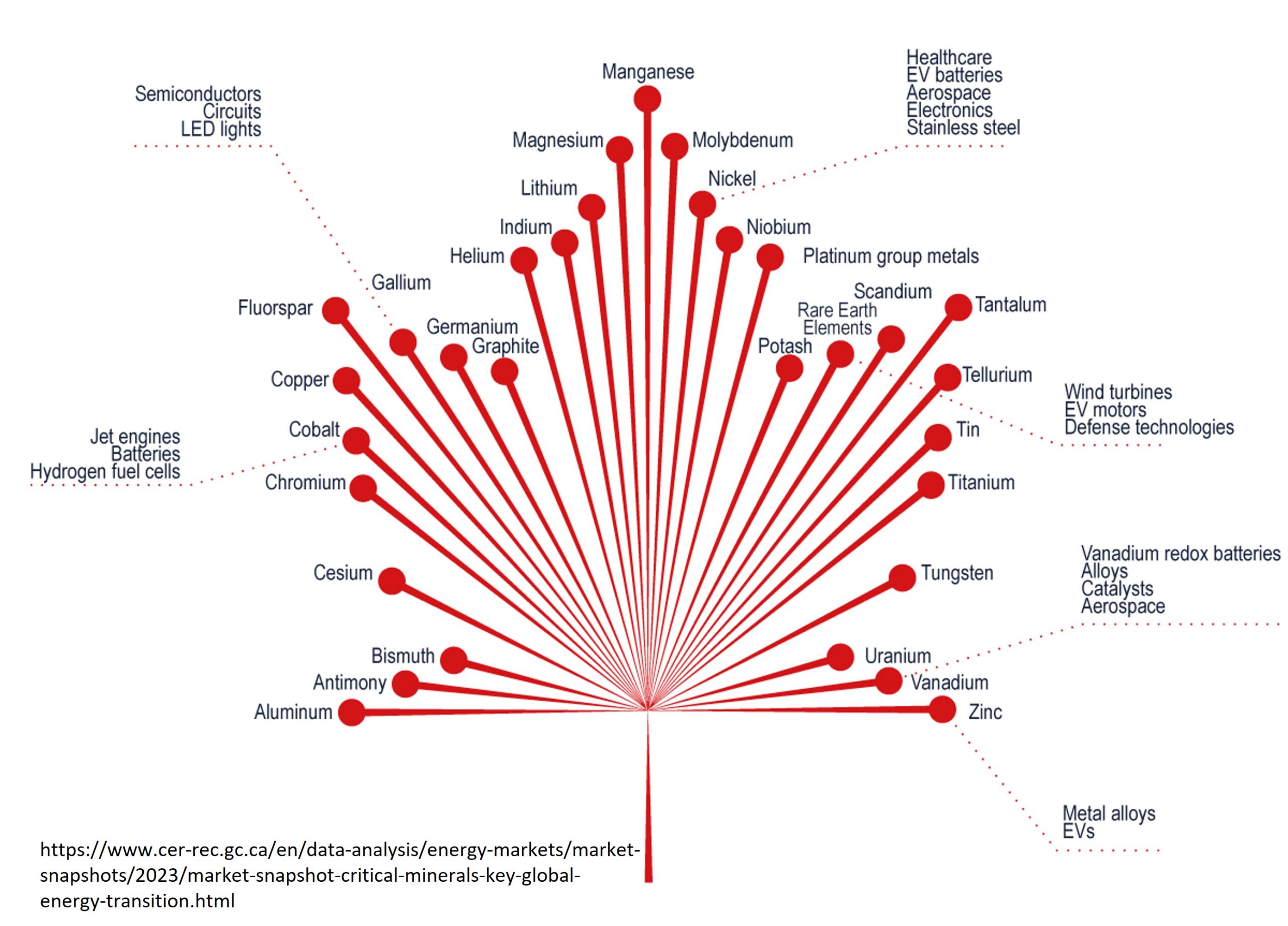

Due to its light weight and high strength, aluminium and its alloys have been used extensively in the aerospace industries and as structural material anywhere a strong lightweight material is required, such as in building frames.

Where is it found?

Bauxite, the principal ore of aluminium, is a relatively cheap commodity. It is very abundant and is found in many parts of the world, particularly in the tropics. Very large bauxite deposits are located in Australia, Brazil, Guinea and Jamaica. Only the largest deposits and those located where the cost of mining and transportation is lowest, are commercially important.

Australia is the top bauxite producing country in the world, accounting for one-third of the world’s overall production. China and Brazil are also major producers.