The mining industry has a productivity problem.

Coming into the last big commodity cycle and for most of the years since, mining productivity has continued to decline. Miners grew too fast during good times and ended up with inefficient, over-sized operations. When things got tough, producers raced each other to the bottom compounding productivity issues from overly complex and unruly operations. While some would argue the problem has stabilized over the last few years, the industry is still markedly off productivity levels from the early 2000’s.

New technology can certainly help improve productivity in some areas of mine development and operation, but these typically provide only single point solutions and are unable to solve system-wide problems rooted in corporate structure. Fortunately, a solution can be found in systems engineering, which has its roots in aerospace.

How do NASA and other aerospace organizations manage complexity while making sure their space systems do not fail? While developing missiles during the early Cold War, the United States Air Force laid the groundwork for the practices that would later send astronauts for the Moon. The Apollo program was most complex project ever attempted in human history. The most impactful innovation of the era was not a rocket, capsule, or spacesuit but systems engineering—the process that wove together the efforts of 300,000 people working for 20,000 contractors and 200 universities in 80 countries. Without systems engineering, Apollo would have been remembered as a spectacular failure rather than one of humanity’s shining achievements.

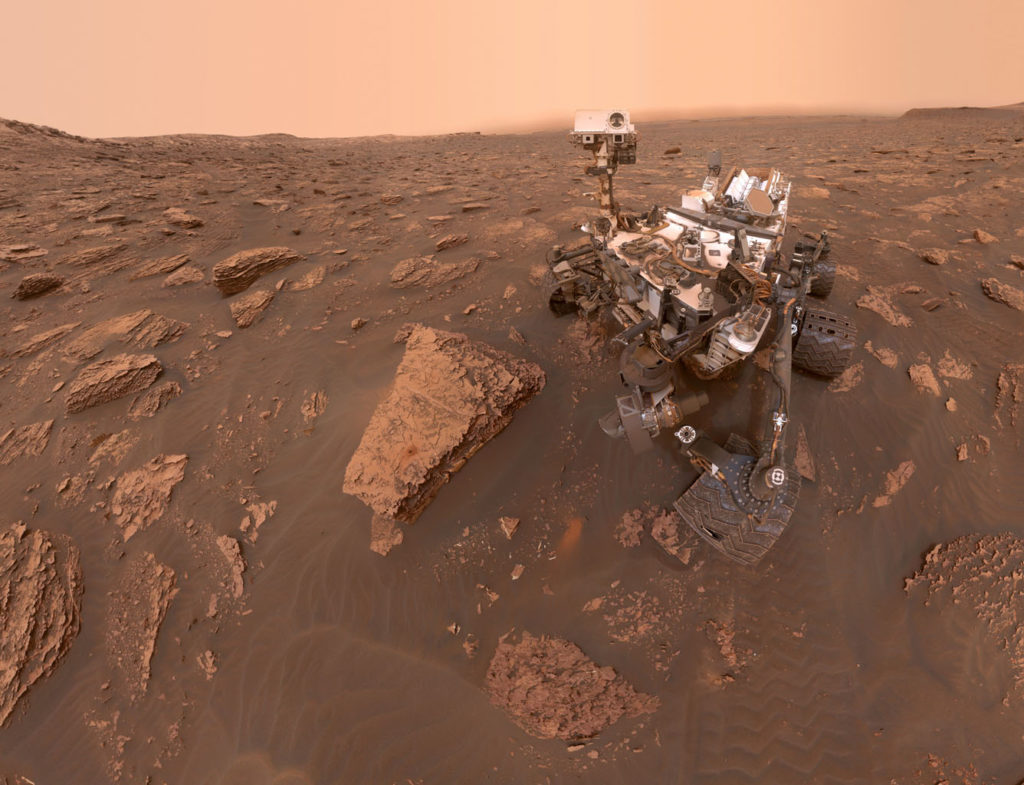

Systems engineering is both a philosophy and a methodology rooted in requirement discovery, definition, and communication. While most organizations rely on heritage, past success/failure, and intuition to guide innovation, systems engineering forces teams to approach each problem with a clean slate and an open mind. The most feasible solution may not be the one you expect, as the Curiosity landing team discovered when they realized the insane-seeming Sky Crane system (see the video below) was more likely to succeed than the airbag systems that previously landed the smaller Pathfinder, Spirit, and Opportunity spacecraft on Mars.

Not all technical solutions are scalable.

Since becoming the standard approach for aerospace projects following Apollo, systems engineering has developed best practices: the NASA Systems Engineering Handbook clocks in at 356 pages. Much of that detail is specific to spacecraft, but the beauty of systems engineering is that it can be distilled to core steps that can be applied to challenges in any sector:

- Define the problem. Study the issue to ensure you’re not addressing a symptom rooted in a deeper problem. Write project requirements that articulate what the system must do without describing how it will do it.

- Guide the development of the optimal solution. Develop technical solutions that accomplish your objectives within defined constraints (e.g. schedule, cost, performance). Revisit project requirements regularly.

- Integrate the system. Put all the parts of your solution together, ensuring that interfaces—where elements of a system meet each other—between people, hardware, software, materials, and processes are working as expected.

- Verify that the solution addresses the problem. Test your solution under the conditions it’s expected to perform in and make sure it addresses the original project objectives.

This process can accommodate dramatic increases in system complexity, often producing revolutionary technologies as a result. Traceability and clear reasoning for decisions creates a lasting connection to the original project goals, potentially decades after the system has been designed and put into operation. The tight control of technology, interfaces, and system optimization allows innovative work to achieve success even across multiple locations, vendors, and stakeholders.

Mines are surprisingly analogous to spacecraft. Though they certainly don’t look similar, they are both complex systems made of elements that can interact in unexpected ways. Like a spacecraft, a mine is only one part of a system whose elements can include people, hardware, software, materials, and processes. Both are so complex that it is impossible for a single person to fully understand and track every element of the system. When NASA’s Curiosity rover sends back images from the surface of Mars, it’s easy to forget that the rover is supported by an operations team working 24/7, global ground communication equipment, millions of lines of code, and hundreds of scientists and engineers. Similarly, a mine is much more than a hole in the ground—it’s also the haul trucks, the operations crew, the global support team, and so on.

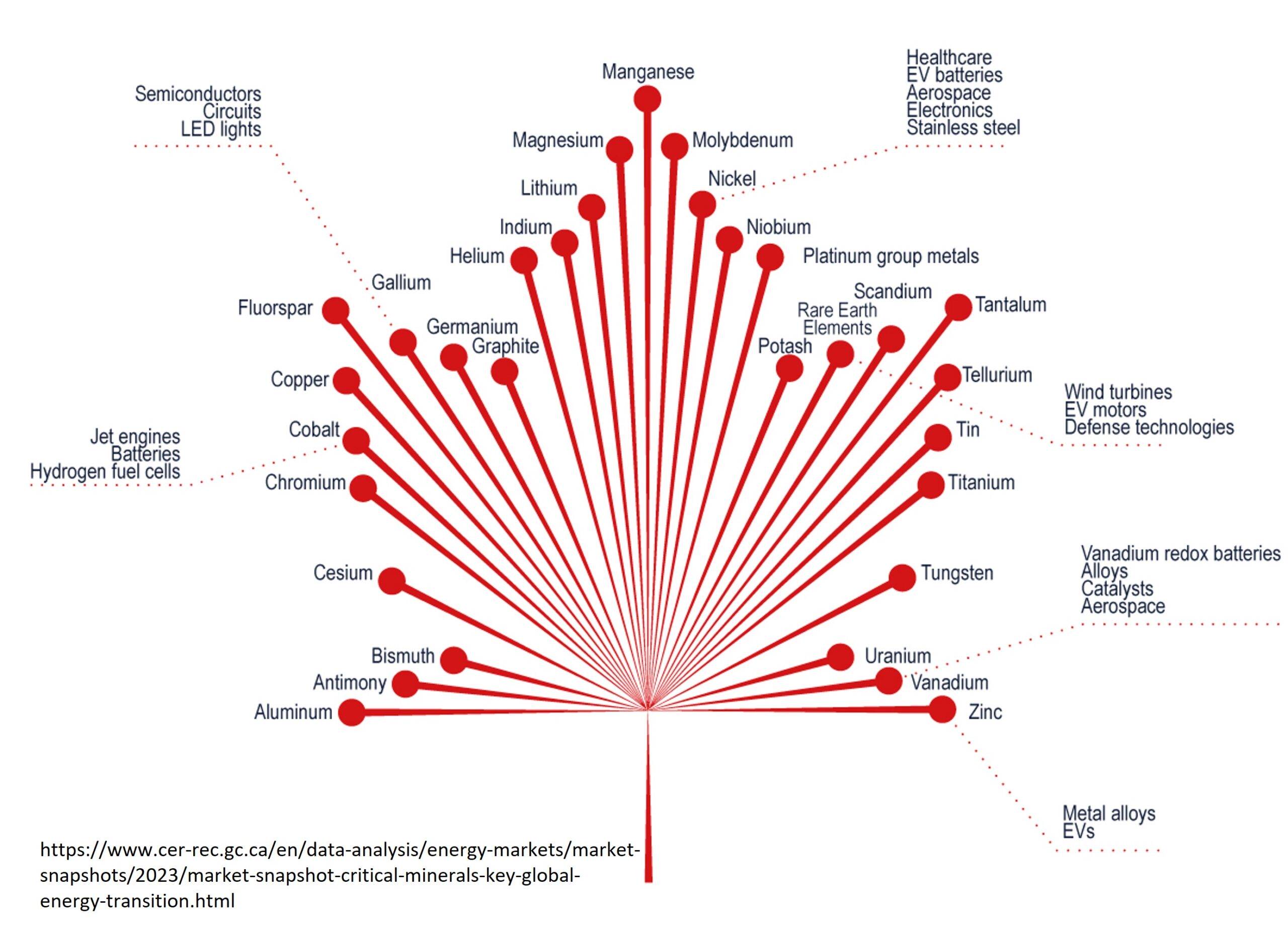

To break through the productivity stagnation, mining companies should understand that the Apollo program didn’t succeed because of an innovative rocket, computer, or astronaut suit. Those technologies solved specific problems, but the real innovation was managing complexity in the face of a nearly impossible task. The legacy of systems engineering can be seen in images and scientific data returned from Mars, the Moon, Pluto, and other places throughout the solar system. By not shying away from complexity, but instead creating structure for it, mining companies can develop solutions are truly innovative.

Further Reading

- Productivity in mining: now comes the hard part. Ernst & Young (2017). PDF

- NASA Systems Engineering Handbook (2017). NASA. SP-2016-6105. PDF

- Johnson, S. B. (2002). The Secret of Apollo: Systems management in American and European space programs. JHU Press. (Book)

- Tracking the trends 2019: The top 10 issues transforming the future of mining. Deloitte (2019). (PDF)

Subscribe for Email Updates