Quality assurance (QA) is a proactive approach to ensuring that chemical analyses of rock and soil samples are correct and accurate. QA systems and procedures occur before a batch of samples is sent to the laboratory for analysis. Typically, QA involves the addition of “check” samples including:

- blanks,

- duplicates, and

- standard samples.

Quality control (QC), in contrast, is a reactive process of analysing the data returned from the lab. This is crucial for determining the quality of data and for revealing any deviations from the norm.

Very proud of his landscaping efforts he showed the geologist who promptly “blew his top”. The gravel had been carefully stockpiled to act as a readily available source of blank material for use during the drilling campaign.

Appropriate QA and QC of samples from both drilling and soil sampling is critical if results are to be trusted by investors and management.

Blanks

A blank sample is added to the beginning of a sample batch. Blanks are used to determine whether a laboratory is clean or not. Busy laboratories are under constant time pressures and when there is a high throughput, mistakes and omissions become a real possibility, even with the best systems in place. It all comes down to human nature and the economics of running a laboratory. All too often, a technician may be under so much pressure that they don’t clean a crusher or ring mill properly before the next sample or batch of samples.

Crushing and grinding equipment is normally cleaned with what is known as a “quartz rinse” i.e. very clean quartz sand.

Blanks are made of local non-mineralised rock. I once knew a contractor who was caught out due to the material’s ordinary appearance. One day while helping with tidying up around a core shed, he helpfully filled in all the ditches and hollows with what he thought was a pile of gravel. Very proud of his landscaping efforts he showed the geologist who promptly “blew his top”. The gravel had been carefully stockpiled to act as a readily available source of blank material for use during the drilling campaign.

Washed river sand is also commonly used as a blank for QA purposes. Again, it can end up as a component of concrete, unless carefully labelled!

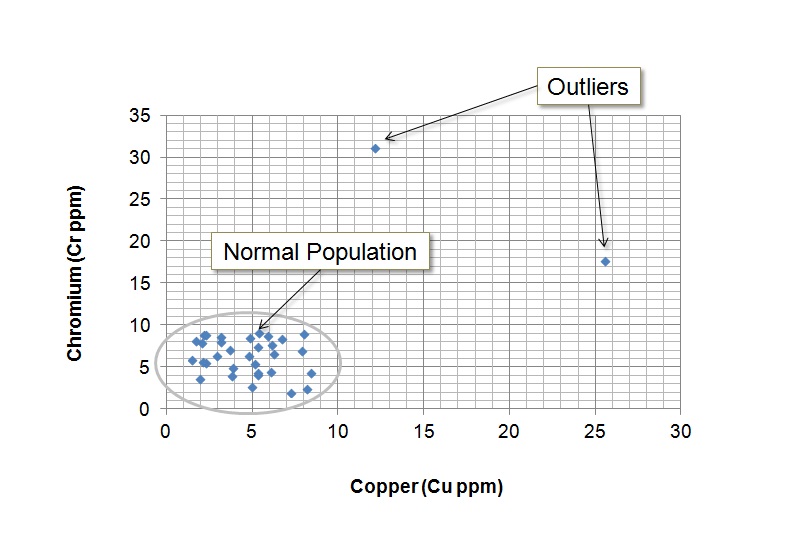

The geologist quickly picks up any contamination issues by plotting two different elements against each other. In the example provided below, two “outliers” plot away from the “normal population”. These deviations were caused by equipment not being cleaned properly prior to starting a new batch of samples.

Duplicates

Duplicates are two identical samples submitted to the laboratory for analysis to detect sample switches and/or cross-contamination issues. They can be submitted proactively with the batch. Alternatively, the same sample can re-submitted later to check if an unusually high result is valid or not.

The reactive approach is not the best approach, because unusually low results may be missed, potentially missing an important result.

Sample switching can sometimes occur at any stage during sample handling. Laboratories normally have in place systems which minimise the potential for this happening.

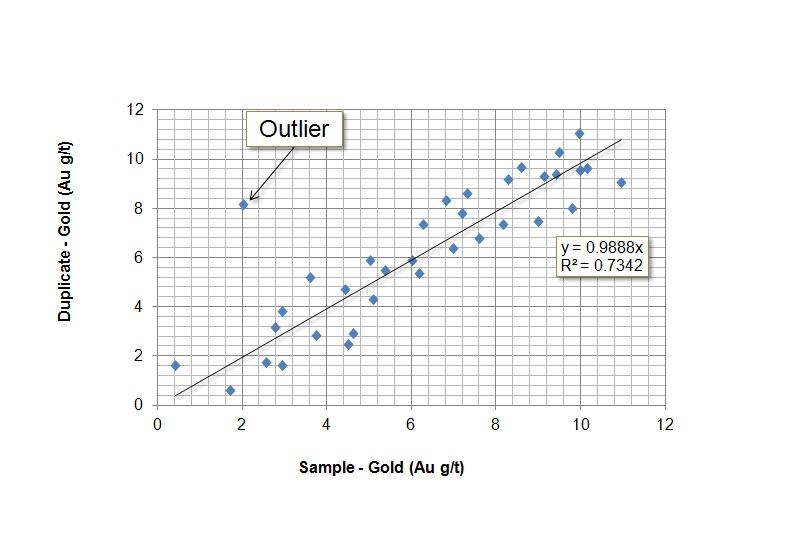

Typically, several evenly distributed duplicate samples are submitted for analysis within a batch. Later analysis of the data through graphing can easily reveal deviations from the trend-line. These sample “outliers” can be repeatedly re-assayed until the geologist is satisfied with the result.

Standards

Standards or certified reference materials are added throughout batches to detect cross-contamination and sample switches. Standards are normally purchased from reputable suppliers however their pre-packaged appearance is a dead giveaway to laboratories. In addition, because they are usually come pre-prepared they do not test the sample preparation stage for cleanliness. Laboratories can become familiar with which result is expected from a standard, even without any identification on the packet.

An alternative is to prepare in-house standards which look similar to regular samples. That way the laboratory has no idea that it is a standard and will therefore treat it like a normal sample. Unfortunately, there is a higher cost associated with doing this as in-house standards need to be assayed several times prior to their routine use, preferably at different laboratories, to obtain an average composition for the material.

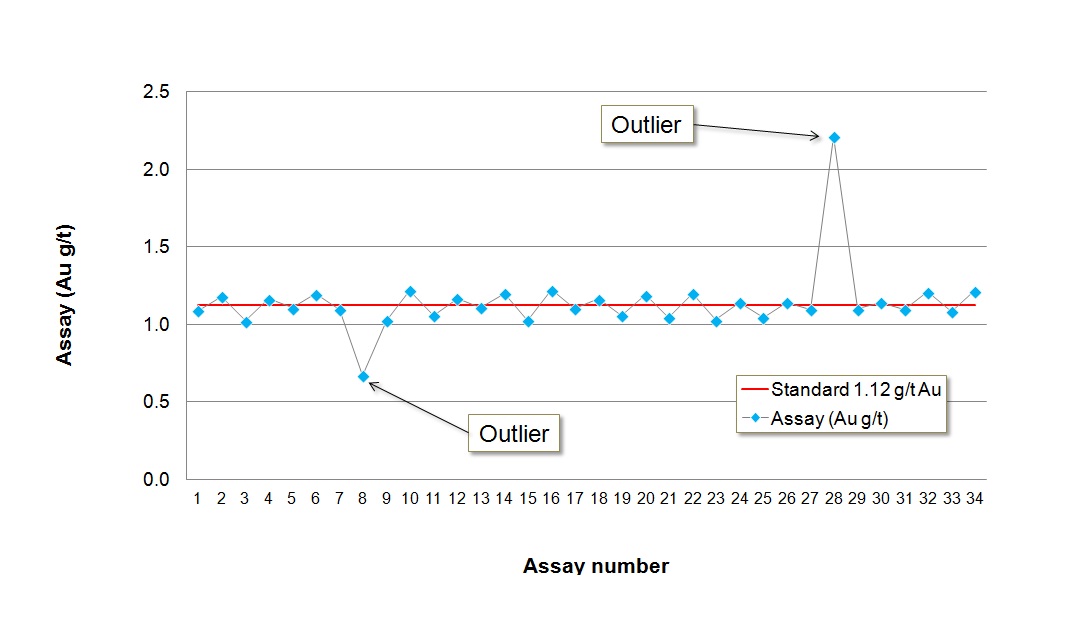

A line-plot of assayed standards will instantly show any deviations, which can then be investigated to identify the cause of the discrepancy.

Line-plot of gold assay values for standards within a large batch or over a period of time. Most of the assays plot close to the standard’s certified gold assay value of 1.12 g/t Au. A couple “Outliers” plot significantly away from 1.12 g/t Au, which may indicate contamination or sample switching.

Other Considerations for Sample QA/QC

Field Contamination of Samples

While collecting rock and soil samples in the field, geologists must always be on the lookout for potential sources of contamination. It goes without saying that all jewellery must be removed during any handling of samples because even the slightest contact with the sample, be it rock, soil or stream sediment, can result in an elevated assay for that particular metal.

Field Security of Samples

Sample security is also important. The geologist should be aware of where and how samples are being stored. Samples should be kept under lock and key to avoid any malicious attempts at deliberate contamination or switching by competing companies or individuals wanting to do harm. Samples should not be left unattended in the back of truck at the hotel. Instead samples should be secured in the truck’s cabin or storage container, or even in the hotel room. A great deal of money is spent collecting samples, so they should be treated like extremely valuable possessions.

Samples Should Be Representative

In other words, assays of samples should represent the material being sampled. When selecting rock chips the geologist should ensure that average looking ones are also selected. If not, bias towards high results will occur. Most geologists are very good at identifying and collecting highly mineralised rock, so investors should always be on the lookout for this practice. In areas of “coarse gold” mineralisation such as Bendigo, Australia, getting a representative sample is a difficult and important issue.

Splitting a subsample from a sample has to be done with care to ensure that the subsample is representative of the sample. Geologists use various techniques for doing this such as “quarter coning” and the using equipment such as riffle splitters and sampling spears.

Summing Up

All data released into the public arena should have undergone QA/QC to ensure that any decisions made by potential investors are based on accurate and truthful data.