Once a potentially economic mineral deposit has been found many different challenges face the company preparing to open a mine. One of the most important factors in determining whether a deposit can be economically extracted is the type of mine that will be required.

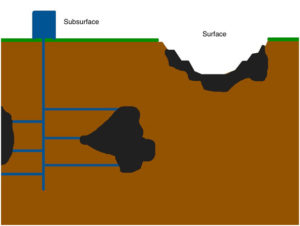

Mining techniques can be divided into two broad categories: surface mining and subsurface mining (See Figure 1). Surface mining consists of stripping soil and vegetation away and possibly a limited amount of rock and then removing ore in large quantities. Conversely, subsurface mining involves sinking a mineshaft and digging tunnels to reach a deposit at depth. These two broad categories encompass almost all mining techniques and will be discussed in detail. As a general rule surface mining is more cost effective than subsurface mining.

The most common surface mining technique is open-pit mining (Figure 1), where a commodity is extracted via an open pit in the ground. This is an extremely cost effect way of removing a resource because large quantities can be removed with minimal effort. Other surface techniques include quarrying and strip mining.

Subsurface mining can be done in many ways with a vast number of terms to describe each type. However all types involve digging tunnels or shafts to access a resource that is too far below the surface or too spread out to use a surface technique and remain economical. The tunnels that are offshoots of the main shaft are termed “drifts”. The commodity is extracted in the subsurface and then brought to the surface for processing and waste rock disposal. Subsurface extraction requires vast amounts of planning because of the increased safety concerns of working underground. A collapse can be costly in more ways than one. Digging tunnels designed to intersect ore bodies isn’t easy either. Complex geometry is used to determine the orientation of the ore body and drifts are constructed to maximize the amount of ore removed, a miss can lead to loss of revenue because large amounts of host rock are removed that do not contain any ore. The smaller volumes extracted only prove to increase extraction costs, which is why higher grades are needed to open a subsurface mine.

Cheap and easy techniques can make a small or low-grade deposit economical, while costly and complex techniques can make a prospective deposit nothing more than a noisy press release

The first, and sometimes only, question to ask is how close is the deposit to the surface? Proximity to the surface plays a major role in determining which mining technique will be used. A small deposit near the surface may very well be economical if open-pit mining can be utilized. However, the same deposit a few hundreds of meters below the surface may prove to be uneconomical due to costs associated with subsurface extraction.

Another factor is the geometry of the deposit(s). For instance there may be multiple small deposits in an area where the construction of a single mineshaft allows for the extraction of more than one small deposit. The deposits may not be horizontally spaced but vertically spaced making the open-pit technique economical for only the upper deposit. Alternatively, the deposit might have a very complex shape, where open-pit mining would involve the removal off a tremendous amount of waste rock. This waste rock can dilute the grade of the deposit and render the deposit uneconomical. In this case subsurface mining could be used because of the precision of the technique – but at a much higher cost.

Host rock can play a key role in mine economics. Subsurface mining techniques may not be possible in a very weak and unconsolidated host rock. Cost associated with stabilizing drifts and risk of collapse may over shadow any potential revenue. On the other hand, unconsolidated and soft host rock is ideal for open-pit style mining because it favors the bottom line (i.e. The less money it takes to extract the resource, the more profitable the operation.)

A high water table and a highly permeable host rock can also create problems when it comes to the de-watering of a mine. In order to combat this, some companies have employed the use of frozen barriers, or ground freezing to literally freeze the groundwater around the mine using refrigeration units and underground piping. Again, this is only appropriate where the deposit is rich enough to warrant the expense.

In-Situ Leaching

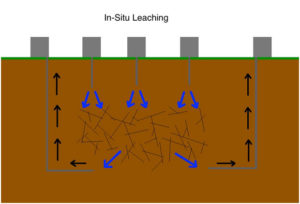

Another more specialized mining technique is in-situ leaching (Figure 2), also referred to as in-situ recovery, or solution mining. This is perhaps the most economical of all techniques, but is only appropriate under certain conditions. In-situ leaching can be conducted without removing any rock at all, but the commodity of interest must be soluble. This technique is used to extract resources such as potash, uranium and copper by pumping leaching solution down holes drilled into the deposit and pumping the solution back to the subsurface. The solution travels through fractures that are either naturally occurring in the rock or produced artificially by hydraulic fracturing. The chemistry of the solution varies depending on what is being extracted. For instance, water is used for potash, acids or carbonates for uranium and acids for copper.

This is not to be confused with heap leaching which is not a mining technique but a method of extracting commodities from mined ore.

Heap leaching works on the same principle as in-situ leaching except that the rock is mined, crushed then piled before the solution is pumped through the rock. It is perhaps most famously used for extracting gold from mines along the Carlin Trend in Nevada. With recent advances in technology heap leaching practices have even been applied to waste rock and tailings sites to extract any remaining ore. A company planning to perform leaching (whether in-situ or heap) does not require very high grade ores and faces fewer logistical problems than a company planning on using any other technique.

Leaching is not without risk and controversy though. The use of acids to extract uranium and copper, and cyanide to extract gold in heap operations has environmental implications. Groundwater contamination and surface run-off are potential problems that need consideration during the mine design process.

Conclusion

Consider this short list of general rules when it comes to evaluating a potential mining operation.

- Surface mining techniques are generally cheaper than subsurface mining techniques.

- The closer a deposit is to the surface the cheaper it will be to extract. The ideal situation is a deposit close enough to the surface to that it can be removed by the open-pit method.

- Consider the geometry of the deposit. Impressive near-surface drill results do not mean that surface mining is possible.

- An unstable host rock makes for a costly and possibly uneconomical subsurface mine.

- In-situ leaching is a very quick and easy method of extraction.

In short, cheap and easy techniques can make a small or low-grade deposit economical, while costly and complex techniques can make a prospective deposit nothing more than a noisy press release.

Subscribe for Email Updates