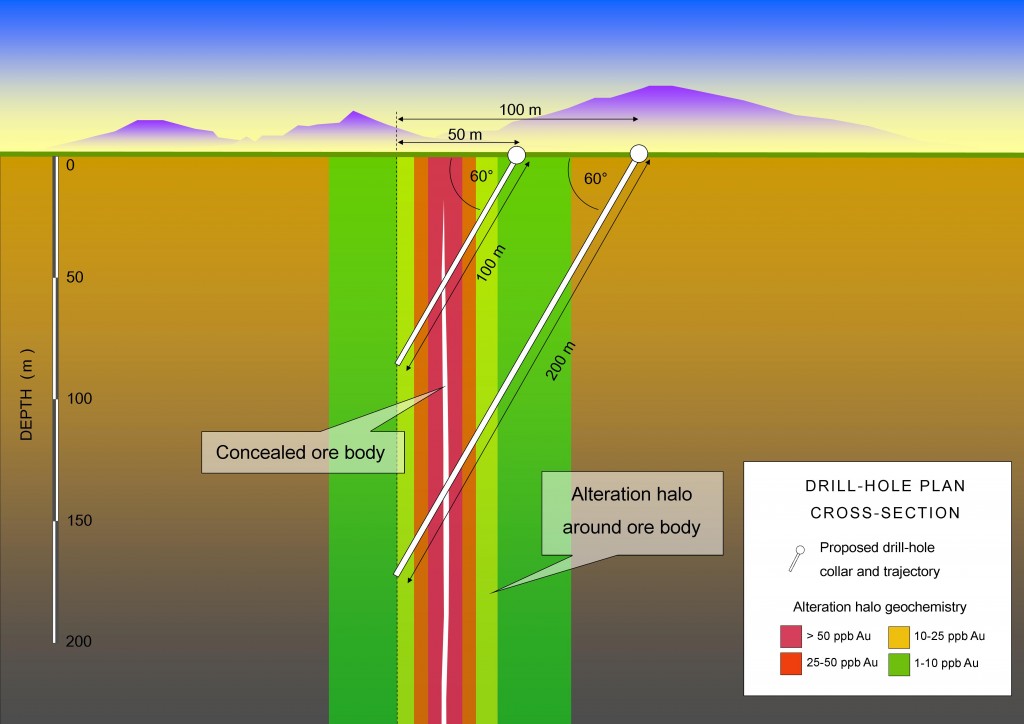

For coal deposits, like most other minerals, drilling is a key to identifying in detail the grade and size of the resource, both prior to mine development, and during operations.

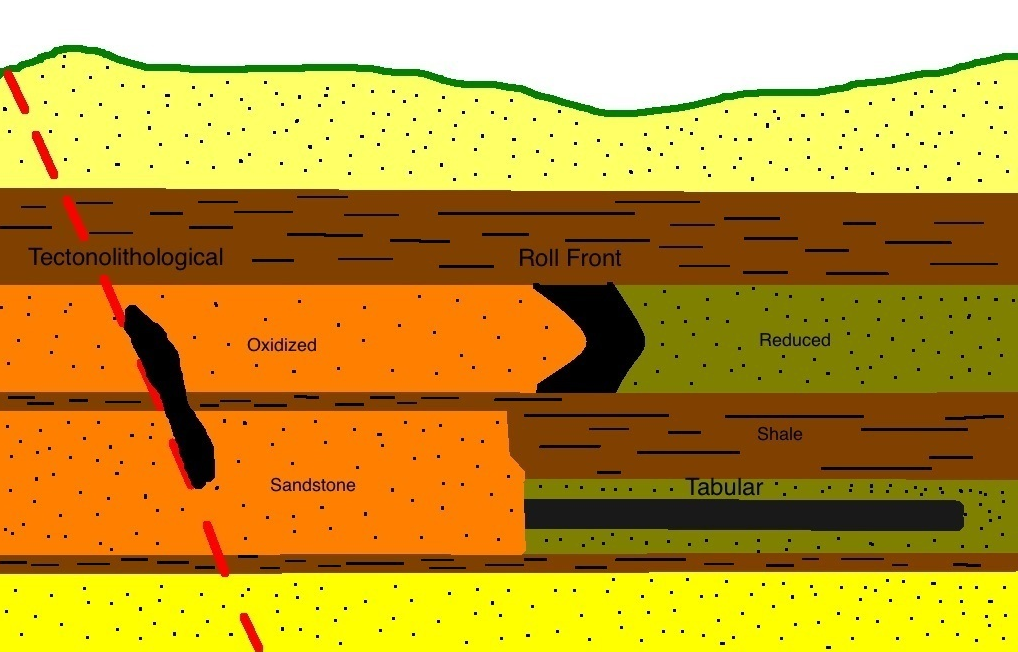

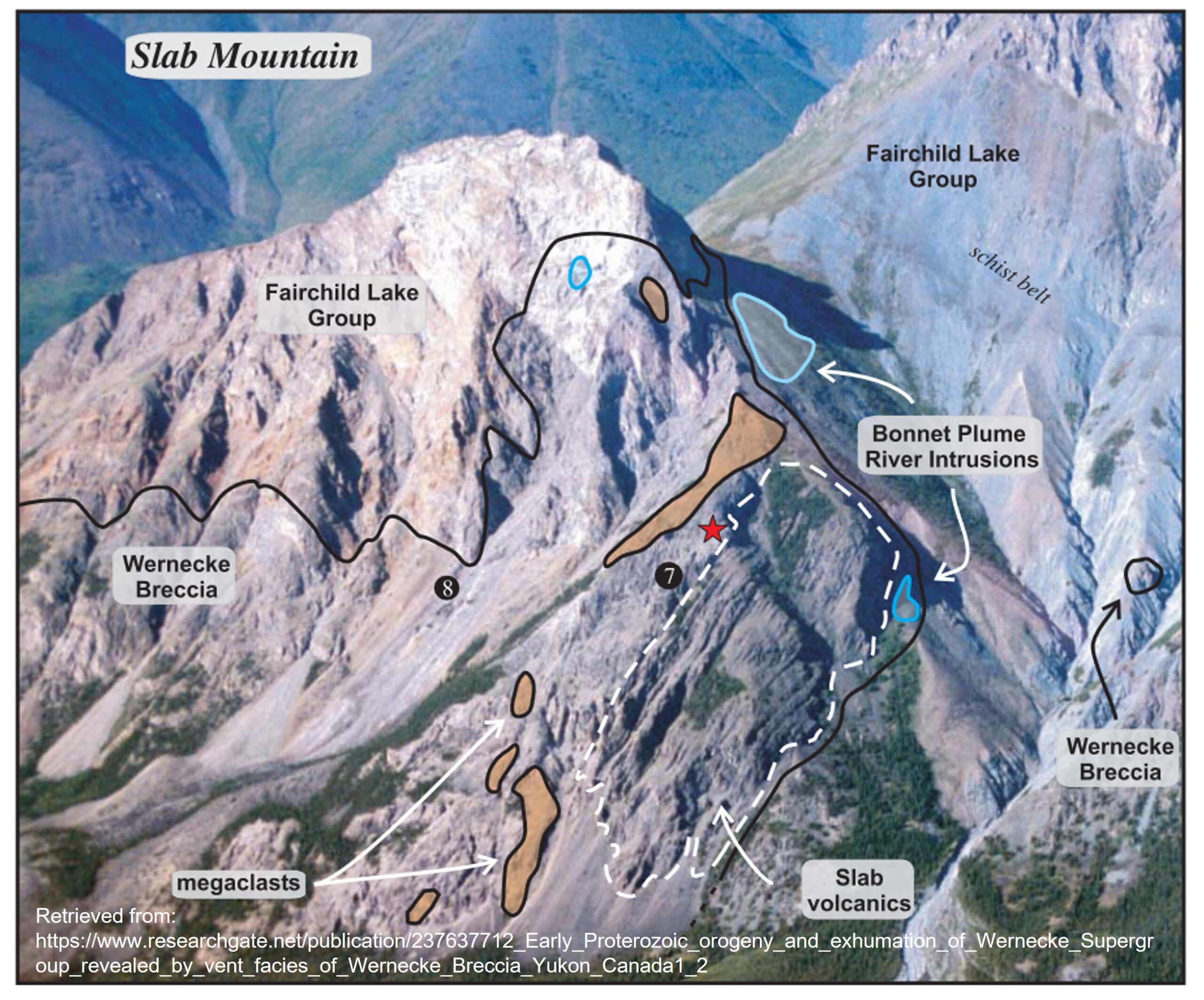

Mining operations employ a variety of drilling methods based on the requirements of the project. In the majority of cases, a drilling program will begin with the exploration phase. The aim is to to confirm survey data about the location and extent of the coal deposits or seams. Additionally, exploration drilling is used to identify or confirm the location of faults, folds, dikes, sills, and other geologic features that may influence how the coal is ultimately mined.

As mining progresses from the initial exploration phase to the latter stages of exploration and into production, a higher level of detail about the site’s subsurface is required.

Initial Exploration Drilling

The initial phase of many exploration drilling programs involves a method known as chipping. True to its name, chipping involves a drill that cuts into the subsurface rock and produces small chips of the material it encounters. These chips range from very small sand particles (<4mm) to larger pebbles (2-3cm). From a geological perspective, chipping is useful for understanding the boundaries of a deposit or seam, but is not so helpful for providing information about the quality or grade of the target coal. Chipping paints a broad picture for mine geologists, and provides crucial information for refining the geologic model of a mine site.

Geologists will sometimes collect samples for geochemical analysis during drilling, but typically, the most important part of chip drilling for a geologist is logging the chips. As the drill advances meter by meter, the chips produced are blasted up the sides of the borehole. When they emerge at the surface, they are caught in a bucket and set out in rows.

One pile of chips is roughly equivalent to one meter of drilling, and this way the geologist are able to log the entire depth of the borehole. Some of the data recorded includes rock type, minerals present, color, grain size, and any unusual traits. Since chips are coarsely pulverized rock fragments at best, when true detail about a deposit or seam is needed mines turn to a different method of data collection.

Detailed Mine Resource Drilling

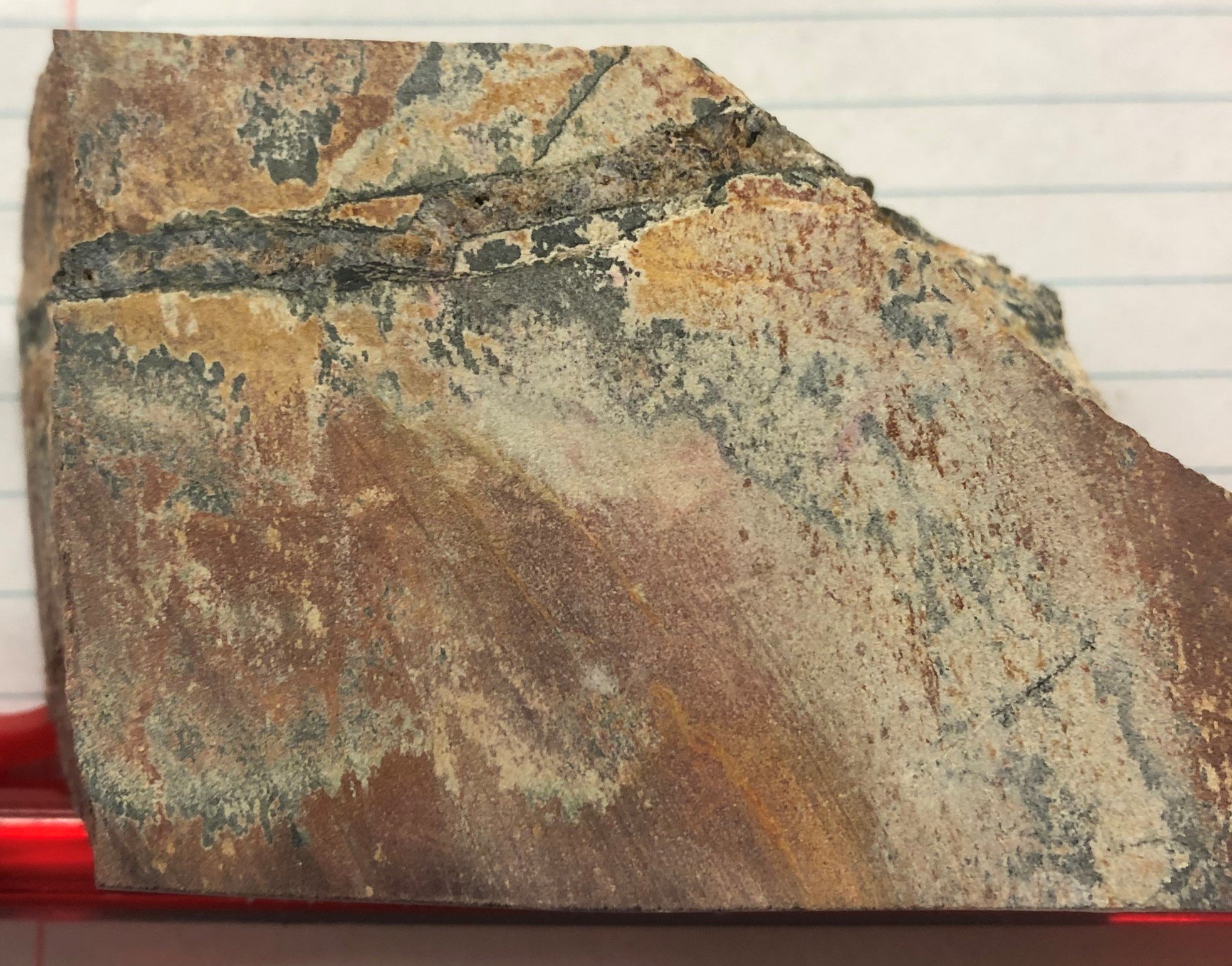

As mining progresses from the initial exploration phase to the latter stages of exploration and into production, a higher level of detail about the site’s subsurface is required. Coring (diamond drilling) is another way of collecting information about a potential coal resource. The drill rig is equipped with a hollow tube, and as the drill pushes the rods into the ground, a cylindrical piece of the rock is pushed into the hollow tube. These samples are usually the length of a drill rod, which is 6 meters. Shorter and longer samples are also possible. The “core sample” is then pulled back to the surface, where the geologist has a few minutes to log the core in detail before the drill rig produces another sample. Time is important during this process, as drill crews are often paid by the number of meters drilled in a day. It is in everyone’s interests to produce good core samples quickly and accurately.

Logging diamond core is slower and more labor-intensive than logging chips, but it produces much more detailed information than chip logging. The information a geologist records may be used to make a rough determination of the quality or grade of a resource at a specific location within the mining lease. Core samples can be used to identify potentially combustible minerals, faults, and other weaknesses in the rock surrounding a deposit. Geotechnical samples of the “roof” and “floor” material bordering a deposit are taken from core samples, and this information is critical to understanding the potential integrity of a mine’s construction.

Unexpected deposits of intrusive volcanic rocks or extremely lithified (hardened) sedimentary rocks can often be seen in core samples, and identifying these is essential when creating a cost-effective mine design. Encountering an unexpected section of very hard rock can derail mine production by hours or even days, which is a delay that mines cannot afford. Core sampling has the ability to pick up finer variations in the country rock than seismic surveys can, and this is why such a labor-intensive process is still used at even the most cost-conscious mining operations.

Subscribe for Email Updates